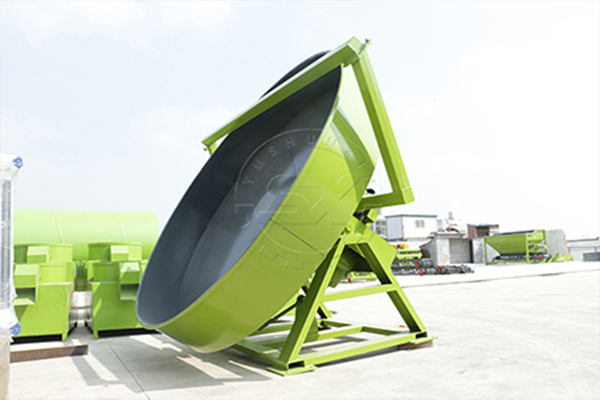

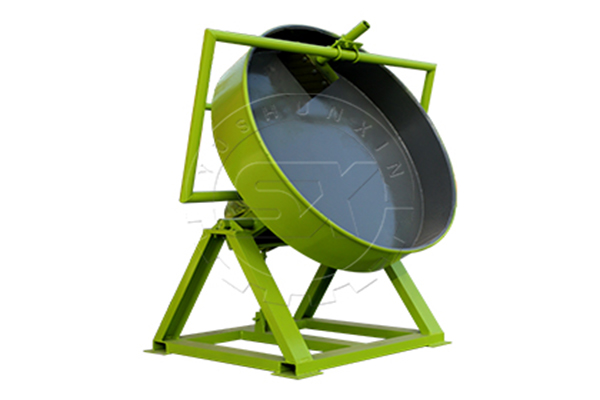

Pan pelletizer is one of popular fertilizer granulator that has won the trust of fertilizer suppliers at home and abroad in YUSHUNXIN. It has a simple design and is easy to operate. But whether you want to process chicken manure, cow dung or NPK into fertilizer pellets, disc granulator can complete it quickly. In addition, this only needs low investment and a small area site. So if you want to start your fertilizer manufacturing business, it will be an ideal choice for you!

What material can pan pelletizer process into fertilizer granules?

In general, material collection is the first step of fertilizer production. At the same time, material also plays an important role in fertilizer granulator purchasing. Is this equipment suitable for processing your fertilizer materials? Pan pelletizer has a high adaptability, which makes it can granulate various fertilizer materials. Such as chicken manure, cow dung, NPK materials, etc.

Chicken manure granulation

Are you looking for a perfect way to recycle manure from your chicken farm? Making it into organic fertilizer pellet is an excellent choice for you. But there is only a small area in the farm, how to make chicken dung into fertilizer granules? Disc granulation equipment can fully meet your requirements. It is a vertical granulation machine. So only needs 3-15 ㎡, it can finish the whole process of chicken manure granulation.

Cow dung fertilizer granules making

When you plan to prepare fertilizer pellets from cow manure, you will find that this kind of material is corrosive. Can disc pellet machine bear this erosion? Of course. The steel type of our pan pellet equipment is Q235B boiler steel, which has a high performance in erosion resistance. So it can help you produce cow waste fertilizer granules for a long time.

NPK fertilizer pellets production

Is this granulator suitable for NPK compound fertilizer pellet making? The answer is yes. Disc granulator can process various N, P, K chemical materials into quality compound fertilizer pellets. So that NPK fertilizer can be stored for a long time and can provide nutrients with crops in a targeted way.

In addition, you also can use disc granulator to make granules from bentonite, akadama, borax, etc powder material. If you are not sure it, welcome to inquire us. What’s more, we offer you disc granulation testing service, which can help you know the granulation effect.

How does pan granulator work to make fertilizer powder into pellet?

After determining that pan pelletizer is suitable for your raw materials, it is necessary to learn how does it work to make these materials into pellet. Commonly, the process of disc granulation is divided into five parts.

Feeding fertilizer powder

At the feed inlet, there is a belt conveyor. It will transport raw materials to disc granulation equipment continuously at a proper speed. Here, to produce higher quality fertilizer granules, it is advisable to crush materials into fine powder. And 50 mesh is the best feeding material particle size.

Adjust the angle of disc

According to local conditions, you may need to produce granular fertilizer with different sizes. How to control pan granulation pellet size? Adjusting the angle of the pan is an excellent choice. Sharper slope, smaller size; slower slope, bigger granules. But please remember that the disc angle must be kept between 40° and 60°. Otherwise, the powder fertilizer cannot form into particles.

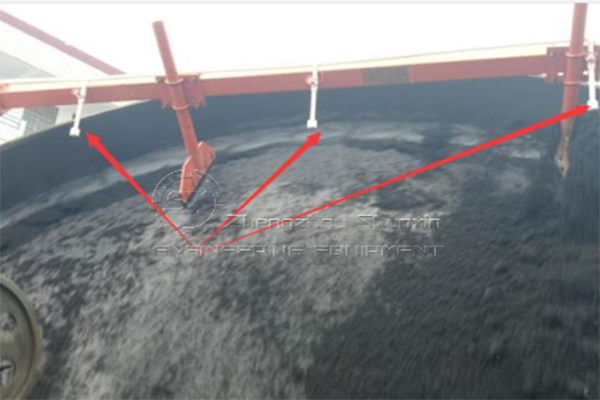

Spray water

Moisture content is essential for fertilizer granulation, it is the same as pan granulation. Because disc pellet machine adopts wet granulation method, which makes use of liquid as binders to facilitate the granulation of powdery fertilizer. Hence, controlling the water content of materials is another way to regulate fertilizer granule size. Less water, smaller size; much water, bigger size. In addition, in order to make it more convenient to control water adding volume, we especially equip a spray system above our pan pelletizer.

Granulation

Then with the rotation of pan pellet equipment, fertilizer powder will be affected by centrifugal force and gravity. So it will roll and form into round fertilizer particles in 5-8 minutes. In this process, by adjusting the pan angle and material moisture content, you can produce organic fertilizer or compound fertilizer with a diameter of 1-8 mm freely.

Discharge

When the size of fertilizer particle meets the required diameter, pan granulator will discharge it automatically. Is it batch by batch? No, it is a continuous process. The unqualified fertilizer pellets will be left in disc and combine with new materials.

Technical parameters of SX fertilizer pan pelletizer

| Model | Dia. of Disc (mm) | Edge Height (mm) | Rotary Speed (r/min) | Motor Power (kw) | Capacity (t/h) | Reducer Model | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| SXYZ-500 | 500 | 200 | 32 | 0.55 | 0.02-0.05 | BYW0-43-0.55 | 650×600×800 |

| SXYZ-600 | 600 | 280 | 33.5 | 0.75 | 0.05-0.1 | BYW0-43-0.55 | 800×700×950 |

| SXYZ-800 | 800 | 200 | 21 | 1.5 | 0.1-0.2 | XWD4-71-1.5 | 900×1000×1100 |

| SXYZ-1000 | 1000 | 250 | 21 | 1.5 | 0.2-0.3 | XWD4-71-1.5 | 1200×950×1300 |

| SXYZ-1200 | 1200 | 250 | 21 | 1.5 | 0.3-0.5 | XWD4-71-1.5 | 1200×1470×1700 |

| SXYZ-1500 | 1500 | 300 | 21 | 3 | 0.5-0.8 | XWD5-71-3 | 1760×1500×1950 |

| SXYZ-1800 | 1800 | 300 | 21 | 3 | 0.8-1.2 | XWD5-71-3 | 2060×1700×2130 |

| SXYZ-2000 | 2000 | 350 | 21 | 4 | 1.2-1.5 | XWD5-71-4 | 2260×1650×2250 |

| SXYZ-2500 | 2500 | 450 | 14 | 7.5 | 1.5-2.0 | ZQ350 | 2900×2000×2750 |

| SXYZ-2800 | 2800 | 450 | 14 | 11 | 2-3 | ZQ350 | 3200×2200×3000 |

| SXYZ-3000 | 3000 | 450 | 14 | 11 | 2-4 | ZQ350 | 3400×2400×3100 |

| SXYZ-3600 | 3600 | 450 | 13 | 18.5 | 4-6 | ZQ400 | 4100×2900×3800 |

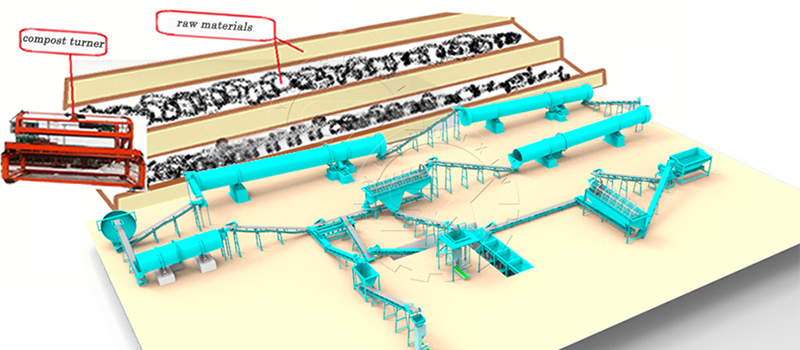

How upgrade the disc granulation system to produce better fertilizer?

If you want to upgrade your disc granulation system or produce better fertilizer pellets, you can choose to establish a disc granulation line.

Before pan pelletizer, you can use dewatering machine, compost equipment, crusher, mixer to make raw materials more suitable for fertilizer granules manufacturing. After disc granulation, you can choose screener, dryer, cooler, coating machine, packaging scale to further improve the purity and quality of granular fertilizer you prepare.

If you are still hesitant about disc granulation line setup, you can tell us your conditions. Such as material, budget, factory area, expectant capacity, equipment you need, etc. We can design fertilizer granulation line design according to your requirements.