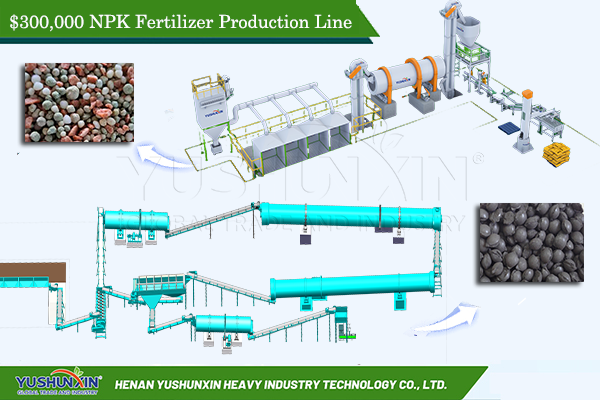

For those who want to invest in NPK fertilizer making line costs $300,000, our engineers has 3 solutions for you. The best choice is disc or drum granulation lines, which can make quality NPK fertilizer. In addition, for no water areas, there is dry roller granulator system on sale. If you want to make profits from NPK fertilizer making, we also can provide you with plans for both high and low quality NPK fertilizer manufacturing. Welcome to contact now for your own NPK compound fertilizer making line.

How to make NPK granules best with $300,000 budget?

If you prepare $300,000 budget for purchasing NPK pellets making machines, we recommend you choose a disc pelletizer line or rotary drum granulation system. They both adopts wet granulation method, which utilize liquid to granulate NPK powder quickly. What’s more, they can finish 1-10 t/h NPK compound fertilizer making easily.

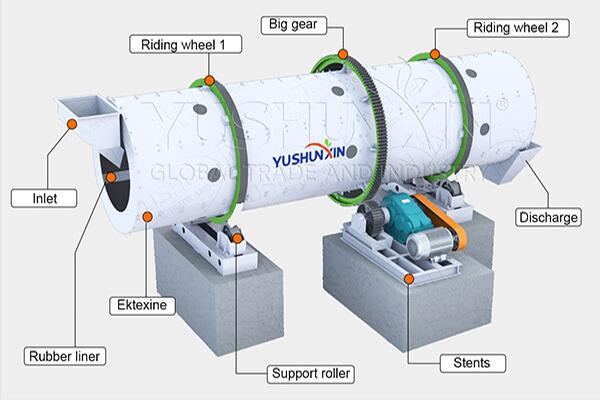

Large NPK Rotary drum granulation line

Provided you plan to invest in NPK fertilizer making line costs $300,000 with large output like 10 TPH, rotary drum granulation line is the best choice. Because it only need one fertilizer drum granulator in the whole process. In addition, compare other NPK fertilizer pellet machines, it has a extra rubber lining which can reduce the erosion from large scale NPK fertilizer manufacturing.

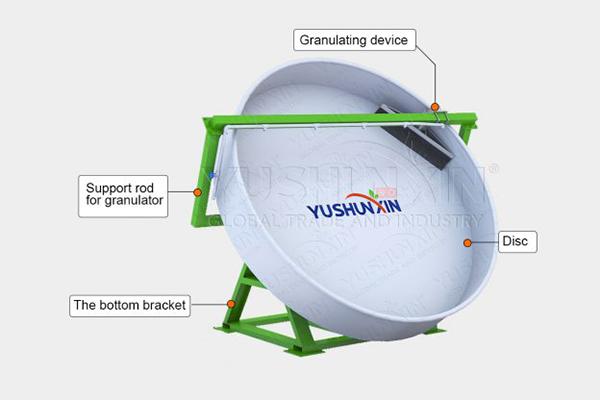

Disc NPK pelleting plan with 93% granulation rate

However, if you need a higher granulation rate in NPK pellets making, it is advisable to buy a disc granulation system. Under the action of disc rotation and liquid cohesion, your NPK granule making rate will be over 93%. In general, the maximum capacity of a pan pelletizer is 6 t/h. So, when set up a 10 TPH NPK granulation line, you usually need to buy 2 sets of SXYZ-3600 disk granulators.

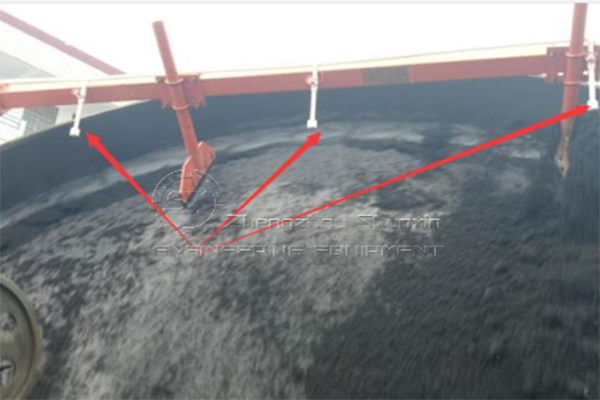

In order to help you produce NPK fertilizer smoothly, we can of you disc pellet machines and rotary granulators with liquid spray device. In this way, you can add liquid or water precisely to keep NPK material moisture to 20%-45%. At that time, the NPK powder will combine into fertilizer granules fastest.

What equipment is needed in the $300,000 NPK granule making solution?

Because of wet granulation method employment, the NPK compound fertilizer granulation line usually contains 8 steps.

Can use dry roller granulator in NPK fertilizer making line costs $300,000?

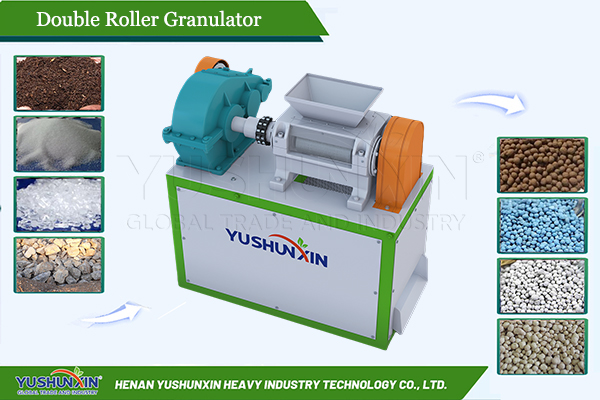

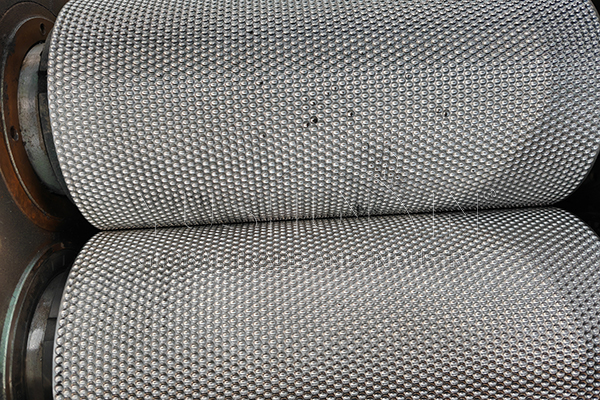

Of course. For dry NPK fertilizer production project, we especially design double roller granulation line for you. Here, the roller press granulator mainly relies on extrusion between two rollers to press NPK into fertilizer granules. Additionally, its feeding material moisture requires less than 10%. Therefore, It is the best choice for making NPK compound fertilizer without water. At the same time, you can reduce the NPK fertilizer making costs of drying and cooling.

In general, a set of roller extrusion granulator can produce 1-3 tons of granular NPK fertilizer per hour. How is it finish the 10 TPH output? Simply, you only need to use more roller granulation machines. For 10 TPH NPK granules making, it needs about 4 sets. Moreover, according to your needs, we can replace rollers with the customized material or size. Such as 4Cr13 stainless steel alloy and for 3mm, 4mm, 5 mm, etc sizes NPK pellets making.

Can you give us a commercial $300,000 cost NPK fertilizer manufacturing plan?

If you want to make more profits from NPK fertilizer making, there also the best NPK fertilizer making line costs $300,000 for you. For this, you can buy two different types of NPK fertilizer making lines.

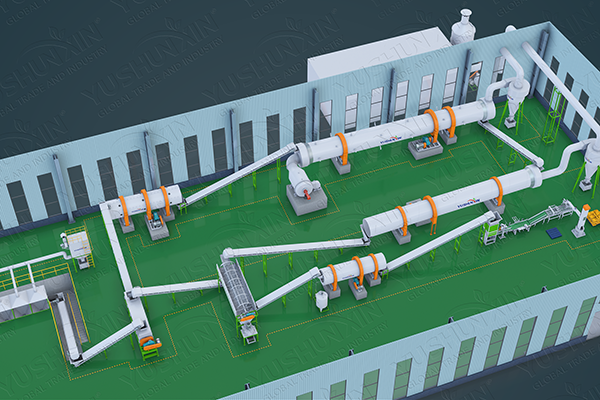

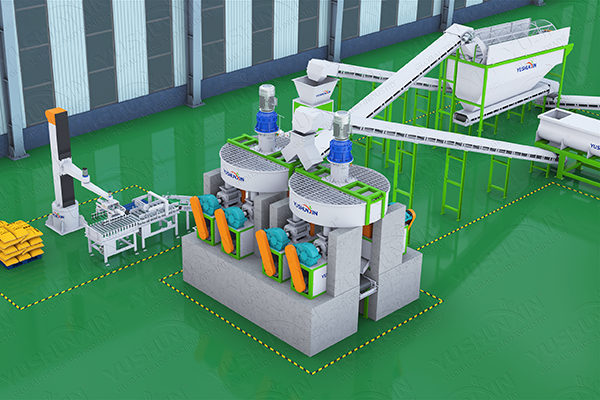

What is the layout of a commercial NPK compound fertilizer production plant setup with $300,000 budget?

One is the NPK granulation system, which mentioned above, the other is a bulk blending fertilizer line.

In this way, your NPK fertilizer plant can meet the requirement for both high-end and low-end markets. Therefore, there is a higher ROI in your $300,000 costs NPK fertilizer making line.

As a professional fertilizer equipment manufacturer, YUSHUNXIN will try our best to offer you the best fertilizer making business plans. For example, we also design NPK fertilizer manufacturing plant designs with other budget. Such as $50,000 cost NPK fertilizer making plant, $100,000 compound fertilizer projects, $500,000 NPK fertilizer manufacturing solution, etc. If you have any other requirements for fertilizer making lines and machines, welcome to contact us immediately