For NPK fertilizer production, most fertilizer manufacturers are prone to turn powder NPK into pellets. In this process, it is necessary to buy a suitable NPK fertilizer granulator. But how choose an ideal fertilizer pellet making equipment for your NPK fertilizer preparation business plan? As a professional fertilizer machine manufacturer, YUSHUNXIN recommend you consider it in three aspects. Scale, cost and material. If you have any other requirements, you can contact us immediately for customization.

What type of equipment is commonly used in small / large NPK fertilizer granulation?

Summarizing the feedback of our past customers, there are two kinds of NPK fertilizer granulators that are popular. Pan pelletizer and rotary drum granulation machine. What is the difference between them? The most obvious difference is that they are commonly used on different scales. For example:

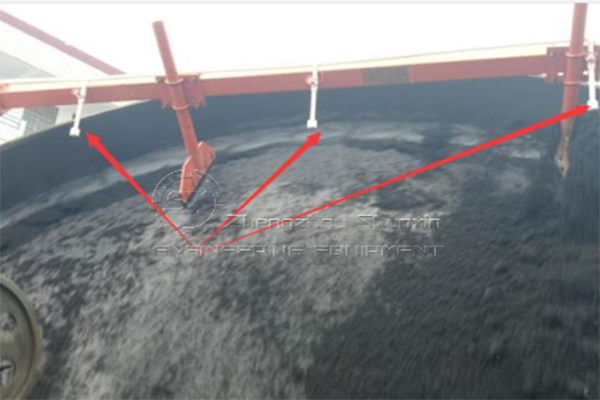

Pan pelletizer for small scale NPK granule manufacturing

If you only plan to start a small scale NPK fertilizer pellets making, we recommend you choose pan pellet machine. A disc granulator can produce 1-6 tons of NPK pellets in an hour. In addition, its granulation rate can reach over 93%. That is, when you use the same amounts of N, P, K to prepare compound fertilizer particles, disc pelletizer can help you granulate more chemical fertilizer powder. There is less material that needs to be returned to re-regulate, so you can finish small scale NPK pelleting effectively.

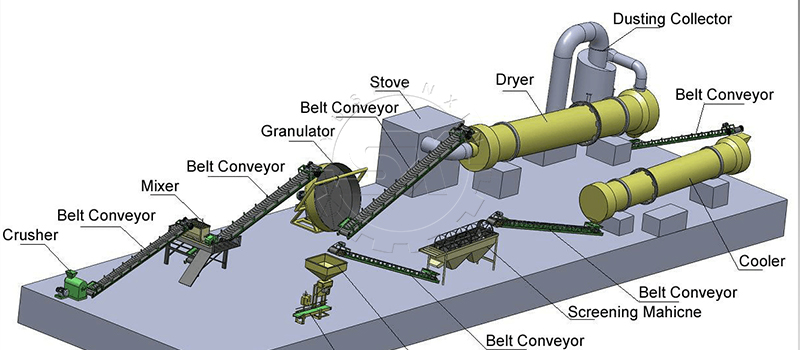

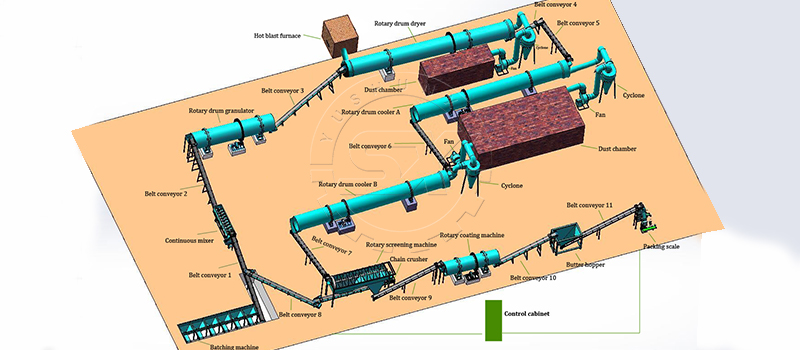

Drum granulation machine for large scale NPK granulation

But for those who want to produce NPK pellets in a large scale, rotary drum granulator is a better choice. There are two reasons. For one thing, it has a larger capacity, which can reach 30 t/h. So it can help you finish large scale NPK granulation more quickly. For another, this fertilizer machine is designed with rubber lining, angle irons and cleaning holes. They greatly contribute to reducing the possibility of wall sticking. Therefore, drum pelletizer can withstand the erosion of a large amount of chemical materials processing.

How much does NPK fertilizer granulator cost?

In addition, in the process of choosing NPK fertilizer granulator, cost is also an item you must focus on. In general, when you plan to buy disc NPK fertilizer granulator for your fertilizer production line, you need to prepare about $1,000-$16,000 for it. How about drum NPK granulation equipment? The price of a rotary drum pellet making machine is $7,200 and $69,000.

How to adjust the pellet size during NPK fertilizer granulation?

Disc NPK pellet equipment

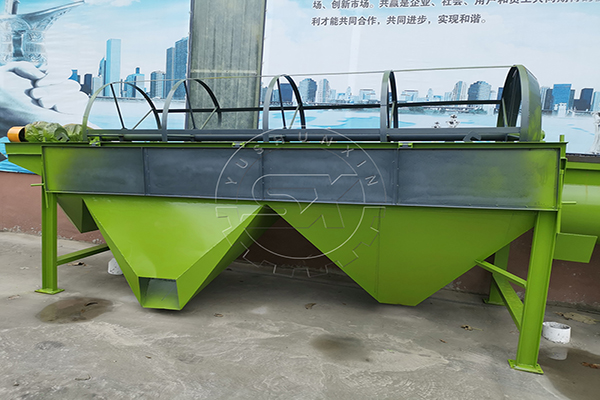

Generally, our NPK fertilizer granulators can fully meet your requirements of making 1-10 mm NPK pellets. However, different pellet equipment has different granule size regulation methods.

Drum NPK fertilizer pellet making machine

Double roller NPK fertilizer granulator

What material can SX NPK fertilizer pelletizers process?

As a professional fertilizer equipment manufacturer, we generally use Q235B boiler steel, which has high erosion-resistance, as material for our NPK fertilizer granulators. So they can be widely used in various N, P, K materials processing. Including urea, ammonium sulfate, DAP, MOP, etc.

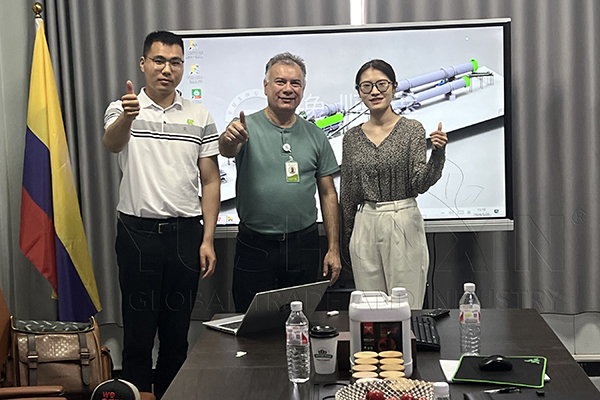

Related successful cases of NPK granule making

In past 20 years, YUSHUNXIN had helped many fertilizer manufactures start their NPK fertilizer granulation plant successfully. Including customers from Colombia, Indonesia, Kenya, Russia, Bolivia, Nigeria, Africa, etc. Such as 10 T/H NPK compound fertilizer making in Egypt, Bentibite granulation in Colombia, Roller granulation plant setup in Indomesia, etc.