When you plan to start organic fertilizer making, cost is an item you must pay attention to. The investment of organic fertilizer plant setup is not fixed. Because it is usually affected by many factors. Such as material, fertilizer shape, capacity, machine configuration, fertilizer equipment manufacturer, etc. But no matter what your budget for organic fertilizer production is, you can find a suitable fertilizer making business plan that works for you in YUSHUNXIN. If you have any requirements, we also can provide you with a customization design for your organic fertilizer manufacturing plant.

What is the cost of organic fertilizer making materials processing?

The cost of organic fertilizer making materials is not high. But when you use different organic materials to produce organic fertilizer, you need to choose different processing methods and machines. For example:

Animal manure

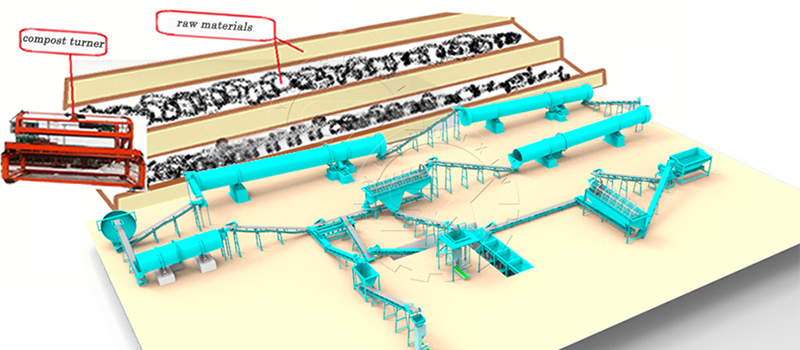

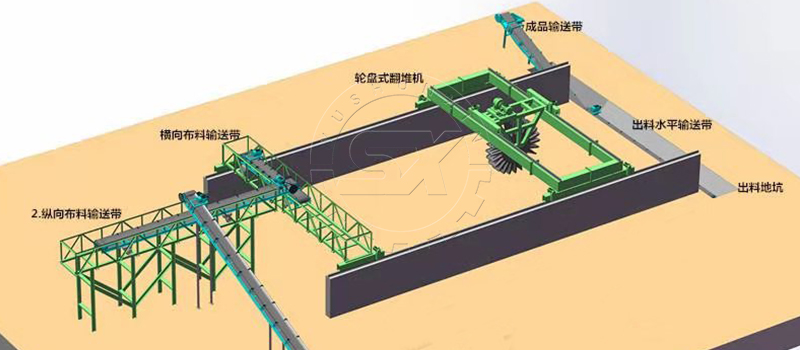

Animal manure is the most common material for the production of organic fertilizer, such as cow dung, chicken manure, pig poop, etc. Because it contains rich nutrients, which are necessary for the growth of crops and plants. But you cannot use animal manure as fertilizer directly. For one thing, it contains many pest eggs and metal elements, which will pollute the soil. So you need to compost animal manure first to eliminate these harmful substances. For another, animal waste usually has a high moisture content, which will affect organic fertilizer making. For this, it is advisable to use manure dewatering machine to remove excessive water from it.

Agricultural waste

In addition, for higher quality organic fertilizer making, it is essential to add suitable agricultural waste as auxiliary materials. Such as straw, sawdust, maize stocks, groundnuts shell, soya bean residues, etc. For these organic fertilizer materials, you also need to make them into compost to kill harmful substances. Moreover, in order to make compost and subsequent compost granulation more smooth, it is essential to grind agricultural litter into a fine powder with fertilizer crusher.

What is the difference in the investment of organic fertilizer plant setup between powdery and granular?

Generally speaking, you can process animal manure and agricultural waste into two forms of organic fertilizers. Powdery and granular. And for them, SX can offer you professional powder organic fertilizer making line and granular organic fertilizer production system. How much do they cost?

Powder organic fertilizer making line cost

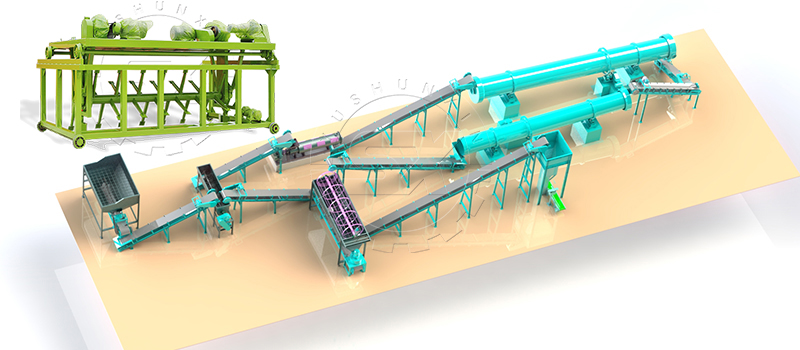

This is a simple process of making organic waste into powder fertilizer. Generally, you only need to purchase 6 kinds of organic fertilizer machines for it. Including compost machine, forklift feeder, manure crusher, powder screener, powder fertilizer packaging machine and belt conveyor. If you want to make use of them to build a powder organic fertilizer production plant, you need to prepare $35,000-$90,000.

Granular organic fertilizer production system investment

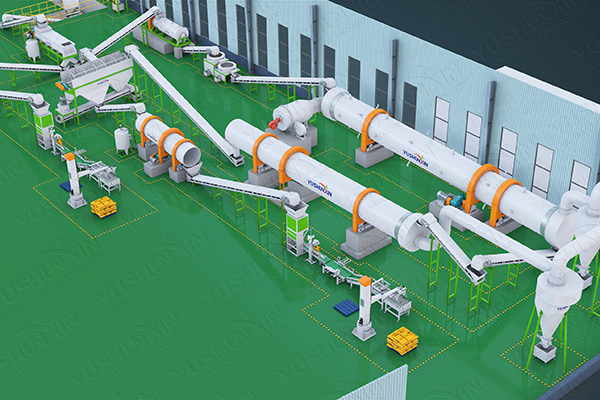

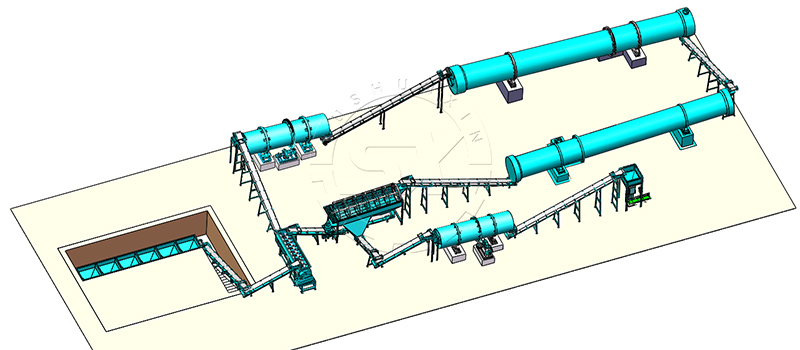

If you want to make more profits from organic fertilizer manufacturing, we recommend you choose our granular organic fertilizer production line. It has a more complicated process than the powder organic fertilizer production line. It mainly needs compost equipment, batching machine, manure crusher, mixer, granulator, granular screener, dryer, cooler, coating equipment, automatic granules bagging machine and belt conveyor. So the budget of a granular organic fertilizer plant setup is $110,000-$550,000.

What can SX do to help you setup an organic fertilizer factory at a lower cost?

If you want to setup an organic fertilizer factory with a smaller investment, it is also necessary to find a reliable fertilizer equipment manufacturer. Here, SX is an ideal choice for you. There are 2 reasons:

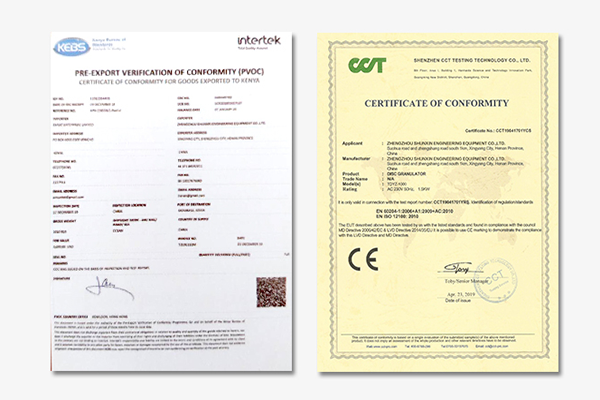

SX can provide you with high quality organic fertilizer plant equipment

On the one hand, we constantly integrate advanced accessories from the domestic and foreign. Such as the Siemens, Schneider, ABB, Baosteel, etc. So we can offer you fertilizer machines with easy and stable operation. On the other hand, all our fertilizer equipment is made of wear-resistant and corrosion-resistant alloy steel. So it has a longer service life than other fertilizer making machines. That is, you can spend less on organic fertilizer plant equipment replacement.

SX fertilizer machines have a more favourable price

As a leading fertilizer equipment company in China, SX has advanced technology and many years of experience in fertilizer processing machine manufacturing. In this way, the cost of fertilizer machine can be reduced. In addition, we are a source factory for fertilizer machine production. This means there is no extra charge during transactions. So you can buy equipment for your organic fertilizer plant setup at a more favourable price.