In-vessel composter is widely used in organic fertilizer composting. Because it has characteristics of high automation, shorter composting time, less pollution and less area occupation. In this way, you can decompose organic materials and eliminate harmful substances quickly and easily. Moreover, in order to meet the different requirements of customers, we especially design various in-vessel fermentation tanks for your choice. Whether you plan to process chicken manure, cow dung or pig waste. Whether you compost organic fertilizer in a small or large scale. They definitely provide you with the best solutions. Even if you want to further process compost into organic fertilizer, we also can offer you suitable organic fertilizer business plans. We will try our best to help you start fertilizer production smoothly.

Why does in-vessel composter play an important role in better organic fertilizer fermentation?

When you start organic fertilizer composting, what kind of compost equipment do you want to buy? Fast composting? Automatic? No pollution? Or small area occupation? SX In-vessel compost equipment can fully meet your requirements. Therefore, in-vessel fermentation tank is a perfect choice for you to facilitate the composting of organic waste.

Fast composting

Composting time is an item all fertilizer manufacturers focus on. In natural conditions, composting will take 2-3 months. How to decompose organic fertilizer quickly? You can choose our in-vessel composter directly. Using it, you can finish the harmless process of organic manure within 10-20 days. Because this compost machine usually prepares organic litter into compost in a closed environment, which can isolate the outside world influence. Such as seasons, extreme weather, etc.

Full automatic composting system

When you want to improve organic waste composting efficiency, the best way is purchasing a full automatic compost system. Here, in-vessel compost system is the optimal choice for you. It adopts a computer control system, which makes the whole aerobic fermentation process work without worker operations. Including aeration, mixing, temperature control, oxygen supply, deodorization, discharge, etc. So only needs 1-2 workers to feed materials, it can prepare a large amount organic litter into compost fertilizer.

Less space occupation composter

In-vessel composter is also the first choice for those who only have a small area for manure composting. Whether it is a trench composting machine or a windrow composter, a larger area is required for organic waste disposal. However, our in-vessel composting facility only needs 10-30 ㎡ to complete 5-102 ㎡ of organic waste fermentation.

Environmentally friendly fermentation

In addition, in the process of organic fertilizer composting, you also must pay attention to the gas waste treatment. For meeting international requirements of environmentally friendly, we especially equip our in-vessel composting equipment with water spray tower and activated carbon box. They can absorb NH3, H2S and other harmful gases caused by fertilizer fermentation to prevent air pollution. Therefore, for producing compost from organic waste without pollution, organic fertilizer fermentation tank is your best option.

Top 4 types of in-vessel compost machines for animal manure disposal

Usually, different fertilizer suppliers have different requirements for composting machine, because there is disparity in their composting conditions. Such as material, it can be chicken manure, cow dung, pig manure or goat waste; capacity, it is small, medium or large scale composting. So we design various in-vessel composting facilities for your choice.

| Capacity (m³) | Motor Power (kw ) | Heating Rod Power (kw) | Hot Oil Pump Power(kw) | Inlet Hydraulic Power Unit Power(kw) | Outlet Hydraulic Power Unit Power(kw) |

|---|---|---|---|---|---|

| 5-50 | 18.5 | 3*10 | 1.5 | 0.55 | 0.55 |

| Model | Heating Power (kw) | Stirring Power (kw) | Feeding Type | Dimensions (mm) |

|---|---|---|---|---|

| SXFT-10 | 4 | 11 | Belt Conveyor | 2400*2400*6900 |

| SXFT-20 | 4 | 18.5 | Belt Conveyor | 3100*3 100*6500 |

| SXFT-30 | 4 | 7.5 | Bucket | 4000*4000*7000 |

| SXFT-100 | 4 | 7.5 | Bucket | 5000*5000*8500 |

What is the cost of an organic fertilizer in-vessel composting system?

When you want to buy an in-vessel composter, the price is an item you must pay attention to. The price of fertilizer composting equipment is affected by many factors, especially configuration. Our in-vessel compost facility adopts many advanced technologies, which are beneficial for better organic waste composting. Such as temperature monitor, oxygen monitor, double insulation, exhaust gas treatment system, full automation control, etc. Therefore, when you plan to start in-vessel composting, you need to prepare $ 19,000-$180,000.

How to further make compost into organic fertilizer?

If you want to make more profits, you can further process compost into organic fertilizer. In general, after in-vessel composting, you can choose to make compost into two forms of organic fertilizer. Powder organic fertilizer or organic fertilizer granule. For this, we can provide professional organic fertilizer manufacturing plans.

Powder organic fertilizer making plan

When you want to make compost into organic fertilizer in a simple way. It is an ideal choice to process compost into powder organic fertilizer. Only needs loader type feeder, crusher, powder screening machine, powder packaging equipment and belt conveyor, you can process compost into quality powdery organic fertilizer. It also has characteristics of low investment, less space occupation, easy operation, etc. So it is the most cost-effective organic fertilizer making line in the market. For example, if you want to buy a 1-2 t/h powder fertilizer production system (including composter), you only need to prepare $35,000 and an 800 ㎡ area for it.

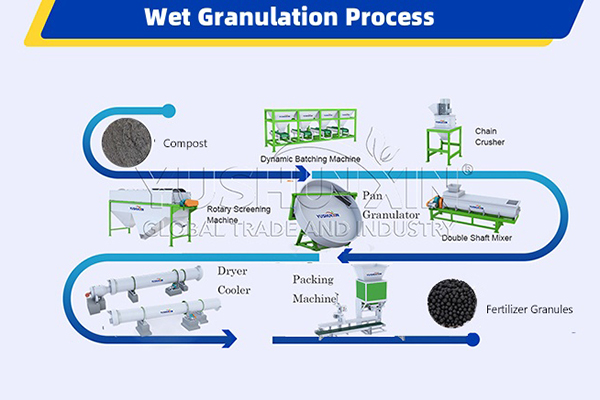

Granular organic fertilizer production line

For those who want to further improve the quality of organic fertilizer produced from compost, we also design granular organic fertilizer production line. Compared to powder organic fertilizer making, it has a more complicated process. Besides, composting machine, it also needs batching machine, crusher, mixer, granulator, screener, dryer, cooler, coating equipment, granule bagging machine and belt conveyor. They can help you turn compost into quality granular organic fertilizer, which has a higher competitiveness in the market. Because granule fertilizer is more convenient to transport, store and use. Therefore, this fertilizer manufacturing system can help you make profits in a shorter time, even less than one year.

Besides organic fertilizer fermentor for fast manure composting, we also design many other machines for fertilizer decomsition. Such as economical windrow compost turner, large wheel type composting equipment, etc. Welcome to contact us for your own fertilizer business plan immediately!