If you have a large and stable organic material source, you can invest in a 50,000 t/y organic fertilizer production plant setup. In this process, you need to pay attention to 3 aspects. Equipment, factory site and budget/cost. In fact, they are closely related to the capacity of fertilizer making. Generally, in order to prevent the service life reduction caused by overloading running, it is advisable to make your organic fertilizer manufacturing system operate for 2 shifts a day and 10 hours a shift. So for 50,000 tons of organic fertilizer making per year, you need to buy equipment with a capacity of 8-10 t/h. In SX, there are various fertilizer production machines for your choice.

3 Items you need to consider when set up a 50,000 t/y organic fertilizer production plant

In general, when you plan to establish a 50,000 t/y organic fertilizer manufacturing factory, you must consider the following 3 items:

Organic fertilizer making equipment in SX

For commercial organic fertilizer making, suitable equipment choosing is important. In this way, you can prepare organic waste into the required fertilizer effectively and economically. Then what equipment is commonly used in organic fertilizer production? Composting equipment, compost crusher, blender, organic fertilizer granulator, dryer, cooler, coating equipment and packaging scale.

Organic fertilizer production factory site

Besides machines buying, you also need to choose a suitable place to install them and start your organic fertilizer making. For one thing, it should be away from residential areas and easily accessible. For another, what’s more, it must be big enough to accommodate your 50,000 t/y organic fertilizer production line. If you have a factory site, we can design a plant layout according to the details you tell us.

Price of fertilizer making

During organic fertilizer production plant setup, cost is an item you must focus on. But usually, it is not fixed and will change with capacity, equipment, design, etc. However, as a source factory, SX will provide you with quality organic fertilizer machines at a favourable price. Even, we can off you organic fertilizer making plan according to your budget.

What business plan can you choose for 50,000 t/y organic fertilizer making factory?

For processing 50,000 tons of organic fertilizer per year, there are two kinds of organic fertilizer making business plans that are popular with manufacturers. Powdery organic fertilizer making line and granular organic fertilizer production system.

50,000 t/y powdery organic fertilizer making line

Do you want to start 50,000 t/y organic fertilizer manufacturing in a simple way, at a low investment or with a small area? Choosing our powder organic fertilizer making line! It only needs several machines: crawler windrow composter,wheel type compost turner, load type feeder, SXFLF-1000 new type vertical crusher, SXGS-1870 rotary screening machine, automatic powder bagging equipment. In general, the less the equipment number, the lower the investment, the smaller the area occupation.

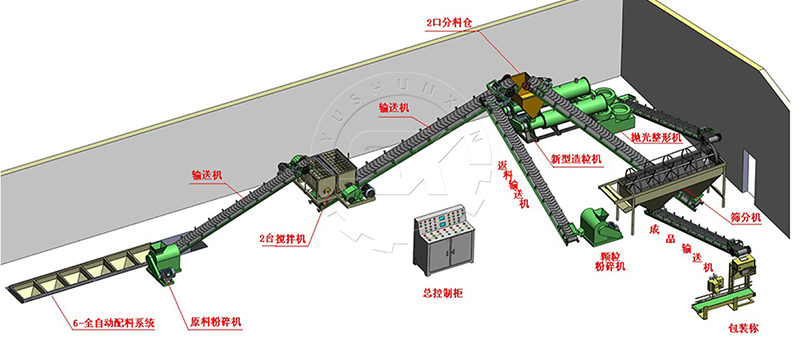

50,000 t/y granular organic fertilizer production system

Can we produce organic fertilizer with a higher commercial value? Of course. Turning organic waste into fertilizer granules. Here, it needs a more complicated procedure for finishing 50,000 tons of organic fertilizer pellets production effectively. Therefore, on the basis of wheel type compost turner, dynamic batching equipment, SXFLF-1000 new type vertical crusher, SXGS-1870 rotary screening machine, you also need to buy SXPJ-3000 disc mixer, 8-10 t/h organic granulator, SXHG-1818 rotary dryer, SXLQ-1818 rotary cooler, BM1600×6000 rotary coating equipment and granule fertilizer bagging scale.

Which granulation equipment is suitable for your organic fertilizer manufacturing?

From the above introduction, we know that granulation plays an important role in organic fertilizer production. However, which granulation machine is suitable for your 50,000 t/y organic fertilizer production plant setup?

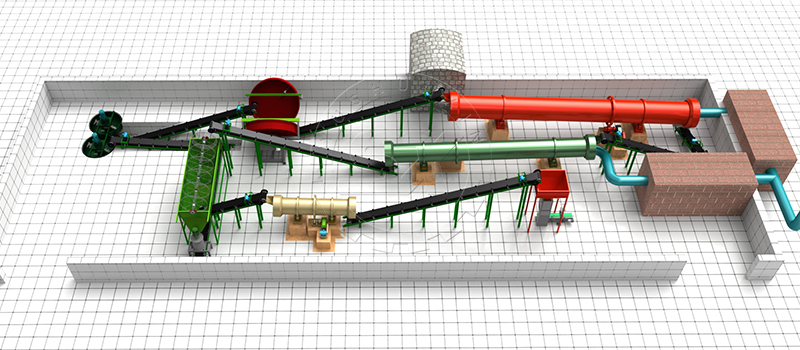

How many areas does the 50,000 t/y organic fertilizer production line cover?

As mentioned above, besides equipment choosing, the factory area is also an item you need to pay attention to. Thus, how many areas does the 50,000 t/y organic fertilizer production line cover?

What is the price of this organic fertilizer making system?

In this respect, SX is the leading fertilizer equipment manufacturer in China, we have our own factory of 40,000 square meters. So as a source factory of organic fertilizer machines, we can offer you quality equipment at an economical price.

Usually, only investing $45,000-$60,000, you can setup an 8-10 t/h powder organic fertilizer manufacturing system. While a complete 50,000 t/y granular organic fertilizer production line needs an investment of $200,000-$360,000 (reference price). If you want to get the precise quote of your organic fertilizer making plant setup, contact us immediately!

Technology parameters of equipment can be used in 50,000 t/y organic fertilizer production plant

| Equipment | Model | Capacity (T/H) | Power (KW) | Dimension (MM) | Quantity |

|---|---|---|---|---|---|

| Crawler windrow composter | SXLDF-3000 | 1300-1500(m³/h) | 156 | 1-2 | |

| Wheel type compost turner | 1 | ||||

| New type vertical crusher | SXLFL-1000 | 8-15 | 37 | 2150*1220*2700 | 1 |

| Disc mixer | SXPJ-3000 | 8-12 | 15 (motor) | 3000*3000*2000 | 1 |

| Rotary drum granulator | SXZGZ-2080 | 8-15 | 18.5 | 8000*2000*2000 | 1 |

| or Pan pelletizer | SXYZ-3600 | 4-6 | 18.5 | 4100*2900*3800 | 2 |

| or New type organic fertilizer pelletizer | SXJZ-1200 | 4-6 | 90 | 4900*2550*1800 | 2 |

| Rotary screening machine | SXGS-1870 | 10-15 | 5.5 | 1 | |

| Rotary drying machine | SXHG-1818 | 7-12 | 1 | ||

| Rotary cooling equipment | SXLQ-1818 | 7-12 | 1 | ||

| Rotary coating equipment | BM1600×6000 | 7-15 | 11 | 6000*1600*1600 | 1 |

| Automatic packaging scale | 1 | ||||

| Dust collector | |||||

| Belt conveyor |

Besides, we also design customized design for 100,000 annual organic fertilizer plant setup, 30,000 t/y organic fertilizer making, 20,000 t/y production of organic fertilizer, etc. Welcome to contact us for your customized fertilizer business plan immediately.