In general, when you plan to prepare NPK fertilizer, there are two methods that are popular with NPK fertilizer manufactures. They are NPK fertilizer granulation line and NPK fertilizer blending system. The former can help you turn powder chemical fertilizer into NPK fertilizer pellets. While the latter can process granular chemical fertilizer into NPK fertilizer you need. You can choose one from them according to your material, budget, factory area, etc. If you have any requirements, you can contact us immediately for solutions. We can provide you with customized NPK fertilizer plant design.

How to choose materials for your NPK fertilizer manufacturing?

For NPK fertilizer preparation, the first step is material selection. For this, there are two items you need to focus on when choosing the materials for NPK fertilizer production.

NPK fertilizer making materials types

NPK fertilizer making, as the name suggests, is prepare fertilizer which contains rich elements of nitrogen, phosphorous and potassium. Then what material can supply nitrogen, phosphorous and potassium elements in your fertilizer making process?

NPK fertilizer preparation materials shapes

Provided you plan to produce NPK fertilizer with NPK fertilizer granulation line, we recommend you choose powder chemical materials. But if you prefer NPK fertilizer blending system, you should buy granular N, P, K materials.

How to make powder chemical materials into NPK fertilizer granules?

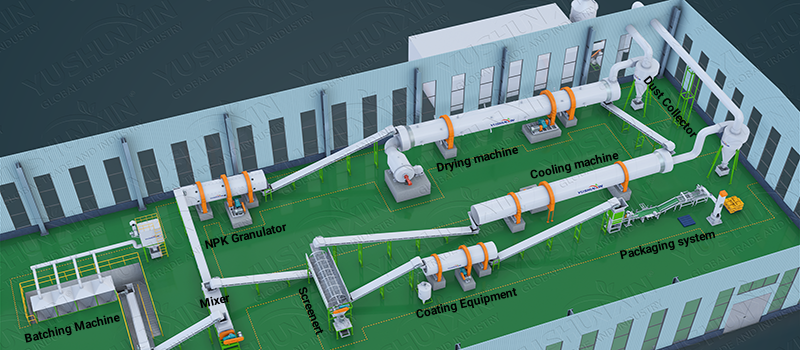

If you plan to prepare NPK fertilizer which can help you make more profits, our NPK fertilizer granulation line is an ideal choice for you. It can help you make powder chemical materials into NPK fertilizer granules quickly and easily. Then what is the design of NPK fertilizer granulation line?

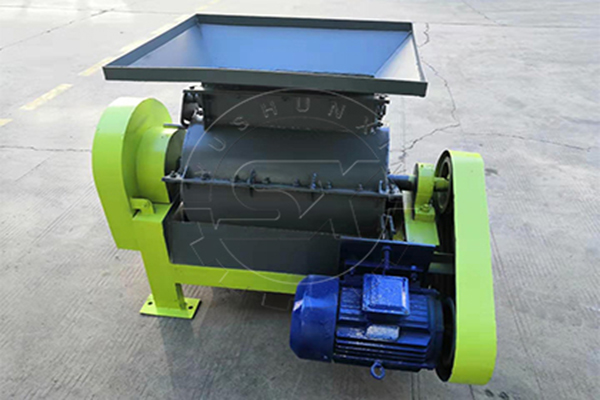

Chemical material crusher

The finer the chemical powder, the better the final NPK fertilizer pellets quality. Therefore, a suitable crusher is necessary for your NPK compound fertilizer making. Here, vertical type crusher and cage crusher are both excellent choices for you.

Dynamic batching machine

You may want to produce 15-15-15 NPK fertilizer or 20-10-10 NPK fertilizer, how to make the proportion of N, P, K is in line with your formula? Our dynamic batching machine equips each material hopper with an electronic belt scale. In this way, it can feed materials precisely to make required NPK fertilizer.

Compound fertilizer granulator

Granulation equipment plays an important role in the preparation of NPK pellet fertilizer. It is used in making powder chemical materials into granules. For NPK fertilizer granulator, we can offer your disc pellet machine, rotary drum pelletizer and double roller granulation machine.

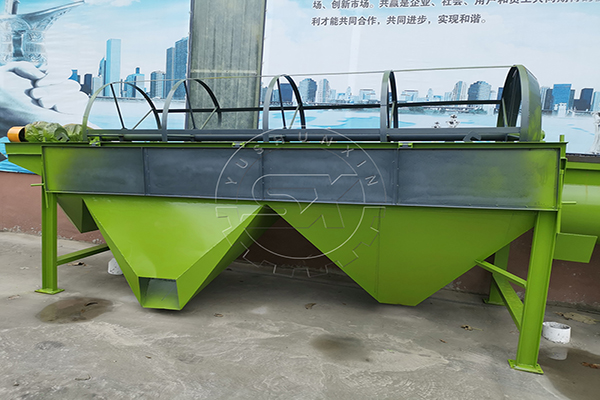

Rotary granules screener

After granulation, in order to ensure the quality of NPK fertilizer pellets you produce, it is advisable to sieve them with rotary screener. Which can separator required size NPK granules from others. Then you can transport qualified granular NPK fertilizer to the next process.

Dryer and cooler

If you use double roller granulator to prepare NPK fertilizer pellets, it is dispensable to buy dryer and cooler. However, when you start NPK fertilizer granulation with disc granulator or rotary drum pelletizer. You’d better use the dryer and cooler to remove excessive moisture from your NPK fertilizer.

How to prepare NPK fertilizer with NPK fertilizer blending line?

Are you finding an economical NPK fertilizer plant design? You can choose NPK fertilizer blending line. But for it, you need to use granular chemical fertilizers as materials. Then how does it work to process them into required NPK fertilizer?

Which NPK fertilizer making line is more suitable for you?

Do you know which NPK fertilizer manufacturing system is more suitable for you? Here, you can consider it from the following 4 items:

Are you making NPK fertilizer from powder or granules?

When you use powder or powder + granular chemical materials, we recommend you choose NPK fertilizer granulation line. However, when it comes to granular complex fertilizer materials processing, it is advisable to setup a blended NPK fertilizer making plant.

What cost of NPK fertilizer plant you plan to invest in?

For those who have enough budget for NPK fertilizer manufacturing – $100,000-$400,000, our NPK fertilizer granulation system is your optimal option. Adversely, if you need a NPK fertilizer plant design for low cost production ($20,000-$100,000), you can choose NPK fertilizer mixing line.

You want to produce NPK fertilizer in a small or large scale?

These two NPK fertilizer production plans both can be used not only in small scale NPK fertilizer making, but also in large scale NPK fertilizer production. But there are also some differences between them. The largest capacity of NPK fertilizer granulation line is 30 t/h. But the large scale NPK fertilizer blending system can process 20-40 tons of NPK fertilizer per hour for you.

How many area you prepare for NPK fertilizer plant setup?

If you have a over 1500 ㎡ workshop for NPK fertilizer preparation, NPK fertilizer granulation line is your best choice. In addition, for starting NPK fertilizer making in a small place of 500-1500 ㎡ area, we also can offer you NPK fertilizer blending system.

What more manufacturers want to know about NPK fertilizer manufacturing?

About NPK fertilizer production, you may have many other things want to know. There are some items commonly asked from our customers – NPK fertilizer manufacturers for your reference. If you need more information of NPK fertilize making and machines, welcome to inquiry us immediately.

Besides NPK fertilizer making plan, there also many other solutions for compound fertilizer making, such as SSP phosphate fertilizer production, limestone to fertilizer project design, bentonite granulation plan, etc. Welcome to contact us for your own fertilizer making business plans.