When you want to start making organic fertilizer in a large quantities, you need to pay attention to 4 aspects. Material supply, fertilizer machine choosing, budget, workshop area. That is, how to ensure a stable material supply for large scale organic fertilizer making? What equipment is suitable for preparing organic fertilizer in a large quantities? How much does the large scale organic fertilizer production plant setup cost? How much area do you need to prepare for installation? Knowing these, you can start producing organic fertilizer in a large scale smoothly and successfully.

How to ensure a stable material supply for large scale organic fertilizer making?

When you want to start large scale organic fertilizer manufacturing, it is essential to ensure stable sources of your materials. In this way, you can produce organic fertilizer continuously and deliver it to your customers. In general, you can consider it from two aspects:

Ensure the quantity of organic fertilizer making materials supply

That is, when you find material supplier for large organic fertilizer making, it is advisable to choose those who can supply you a large amount of materials continuously. Such as large animal farms, large animal meat selling factories, etc. For example, when you plan to produce more than 10 tons of organic fertilizer from cow dung per hour and work 20 hours a day. You need to find a farm which can generate at least 600 tons of cow dung a day.

Ensure the speed of organic materials transport

In addition, if you want to ensure the table material sources for your large quantities organic fertilizer plant. It is also important to finish organic waste transport faster. For this, there are 2 tips for you. On the on hand, it is an ideal choice to set up your large organic fertilizer plant near the materials sources. On the other hand, you can choose a place with convenient transportation to produce organic fertilizer.

What equipment is suitable for preparing organic fertilizer in a large scale?

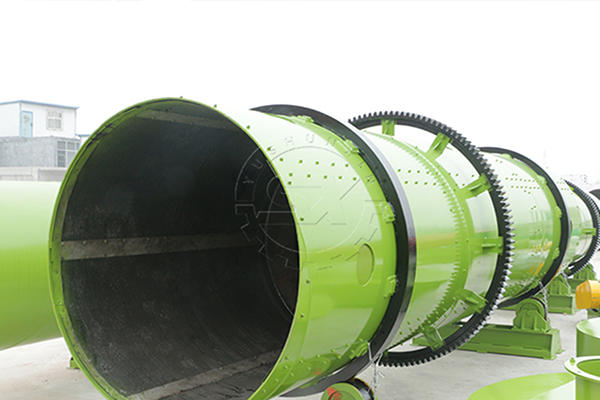

Capacity always plays an important role in fertilizer making machine selection. So Provided you want to produce organic fertilizer in a large quantities, there is no doubt that you need to choose organic fertilizer processing equipment with a large capacity. Then what equipment do you need to buy for large scale organic fertilizer manufacturing? You can choose the following organic fertilizer machines.

How much does a large scale organic fertilizer production plant setup cost?

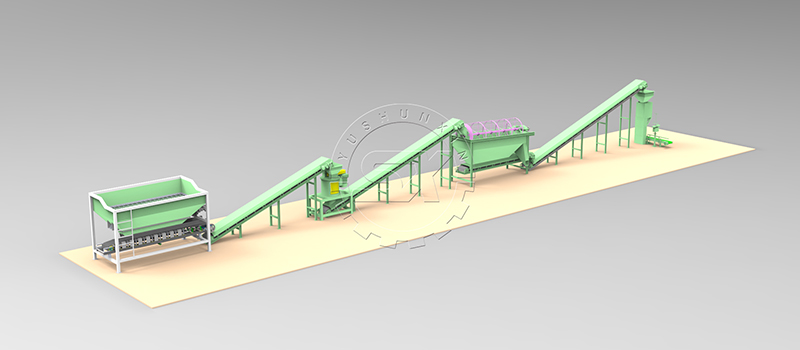

For starting organic fertilizer making in a large scale, cost of organic fertilizer production is also an item you must pay attention to. Generally, by making use of the above large scale organic fertilizer machine, you usually can create 2 types of systems for large amounts of organic fertilizer manufacturing. powder organic fertilizer making line and granular organic fertilizer production line. Then how much do they cost?

10-20 t/h large scale powder organic fertilizer making system price

If you want to start large quantities organic fertilizer making at a low cost, powdery organic fertilizer production line is your optimal option. It simply needs wheel type compost turner, loader type feeder, SXFLF-1000 new type vertical crusher, powder rotary screener, double bucket bagging machine and belt conveyor. The price of a complete 10-20 t/h large scale powder organic fertilizer making system is only $60,000-$90,000.

10-20 t/h large scale granular organic fertilizer production line cost

But it is more complicated to produce granular organic fertilizer in a large quantities. It needs all the above mentioned large organic fertilizer machines. Therefore, for a whole set of 10-20 t/h large quantities granular organic fertilizer production line, you need to prepare $360,000-$550,000 for it.

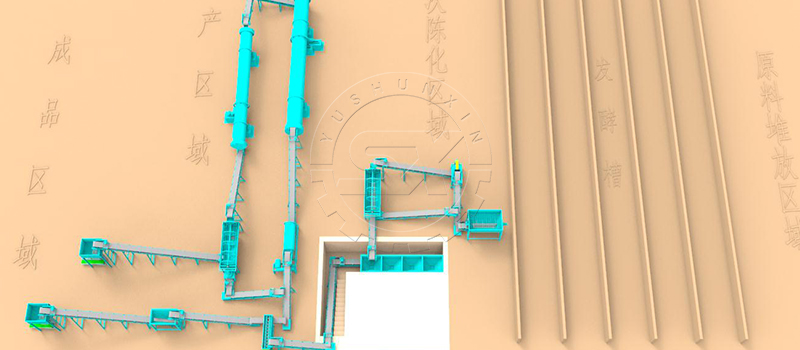

How much area do you need to prepare for the large scale organic fertilizer manufacturing line installation?

Provided you want to run large scale organic fertilizer manufacturing smoothly, you also need to prepare a suitable area for the production line installation. But how much area does it cover?

10-20 t/h powder organic fertilizer preparation line

For 10-20 t/h powder organic fertilizer manufacturing, you need to offer a 3,000-5,000㎡ of area for it.

10-20 t/h granular organic fertilizer making line

But when you want to setup a 10-20 t/h granular organic fertilizer plant, it will need a workshop covering an area of 5,500-110,00 ㎡ .

If you need, there are also organic fertilizer making plans with small scales. Such as 20,000 annual organic fertilizer production system, 30,000 t/year organic fertilizer manufacturing line, etc. Welcome to contact us for your own fertilizer business plans!