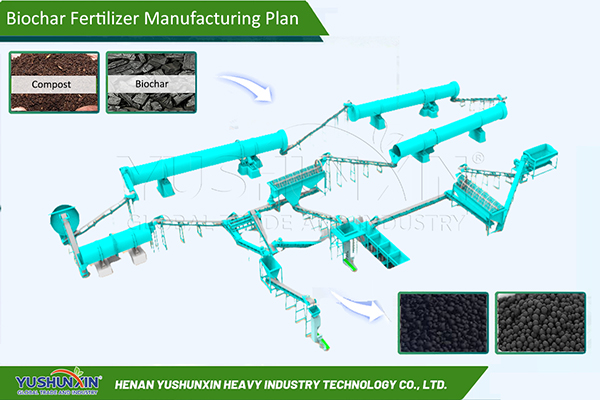

How to make biochar fertilizer? Crushing, mixing, granulation, screening, drying, cooling and packaging. This is a complete process of turning biochar and compost into carbon based fertilizer granules. In addition, if you need a manure compost machine and biomass carbonization equipment, we can also offer you the best equipment. What’s more, according to your budget, we can design customized project for using biochar as fertilizer. Welcome to contact us to get your own fertilizer production system immediately.

Can biochar be used as fertilizer?

Of course. Using biochar as fertilizer is an ideal choice for both disposing of charcoal waste and preparing quality organic fertilizer. In general, making fertilizer with biochar has 2 advantages as follows:

How to make biochar fertilizer?

When you plan to make carbon-based fertilizer, you must learn the major processes of carbon based fertilizer production. Generally, if you use biocahr and compost as materials to make biochar fertilizer, it needs 3 steps:

What carbon-based fertilizer equipment is needed in commercial biochar fertilizer production?

When you want to start a biochar fertilizer plant and manufacture commercial carbon based fertilizer, besides the above equipment, you can add the following to your industrial production system of making fertilizer with biochar.

Can we make fresh chicken dung and biomass waste into biochar fertilizer?

The answer is yes. As a professional fertilizer equipment manufacturer, YUSHUNXIN will design a biochar fertilizer production line according to your actual conditions. When your material is fresh chicken manure and biomass, we can offer you suitable manure composting machines and biomass to biochar equipment.

Do you want to turn fresh chicken manure into compost fast? A suitable compost turner is indispensable. It will turn chicken manure piles regularly to facilitate microorganism activity. This can generate a large amount of heat to kill pathogens, pest eggs and grass seeds in manure. With suitable chicken manure compost machine, you can finish the production of compost within 20 days.

What is the biochar based fertilizer equipment price?

Generally, the price of the system of making biochar fertilizer is not fixed. Because it depends on your capacity, equipment types, project design, etc. The biochar based fertilizer system costs range from $10,000 to $500,000.

- 1

For $10,000-$100,000 budget, you can choose to only buy a basic biochar fertilizer making system, which consists of only crusher and granulator.

- 2

With $100,000-$300,000, we can offer you an upgrading design of biochar fertilizer pulverizer, mixer, pelletizer, screen, dryer, cooler and equipment. With an output of 1-10 t/h.

- 3

With cost of $300,000 to $500,000 or more, you can setup a biochar fertilizer manufacturing plant with the whole process. Including composting, batching, crushing, mixing, granulation, screening, drying, cooling and packaging. The largest capacity can reach make 20-30 tons of biochar fertilizer pellets per hour.

Can you offer pictures of operational biochar fertilizer making plant?

Of course. Over the past 20 years, many biochar fertilizer manufacturers set up their plants successfully and operate well. For example. the biochar fertilizer granule making plant in Indonesia. It is to produce 2-3 tons of fertilizer pellets from biochar and compost. 3-5 mm size. For this, disc granulation line is the best choice. Over 93% granulation rate and can wet biochar compost with 40% moisture effectively.

Compost And Biochar Granule Making In Indonesia

Can we make biofertilizer with biochar?

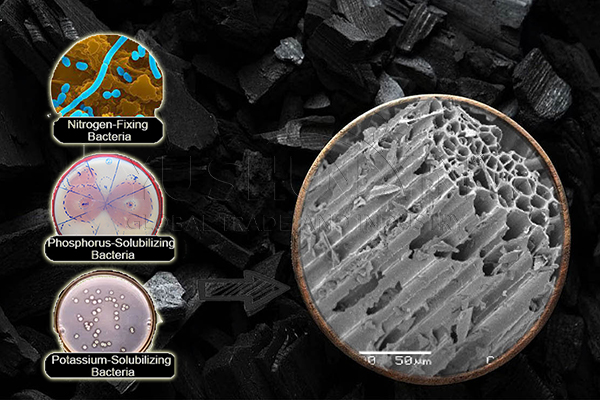

Of course. When it comes to the bio fertilizer manufacturing, besides the nutrient improvement, the biochar is also an ideal choice to use as as a carrier for microbial inoculants.

The porous structure of biochar makes it an excellent medium for hosting microbial life. Its high surface area, water retention capacity, and chemical stability create a protective habitat where microbial inoculants—such as nitrogen-fixing bacteria, phosphate-solubilizing bacteria, or mycorrhizal fungi—can survive, colonize, and function effectively. Compared to traditional carriers like peat or compost, biochar based biofertilizer manufacturing makes final product has a longer shelf life and improved survival rates for microbes during storage and application.

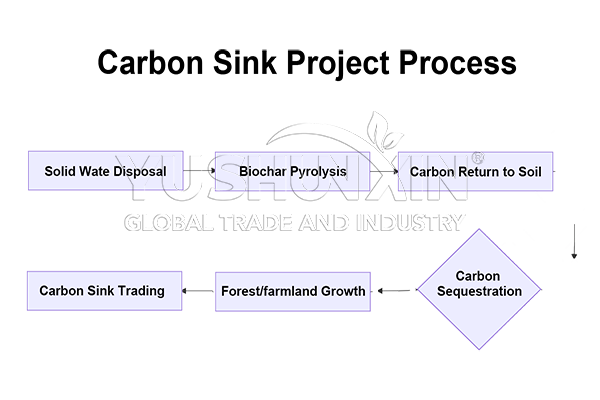

Is the Biochar Fertilizer Making Line Good for Carbon Sink Projects and Carbon Neutrality?

Yes. Whether the biochar pyrolysis system or a biochar fertilizer making line, it is an excellent choice for starting a carbon sink project and contributing to carbon neutrality goals.

Besides biochar fertilizer making, YUSHUNXIN also can offer you many other fertilizer making business plans. Such as cow dung fertilizer production line, chicken manure fertilizer making system, biogas waste as fertilizer design, etc. Welcome to contact us for your customized fertilizer manufacturing solutions immediately!