In order to supply nutrients to the growth of crops and plants more efficiently, it is necessary to start bio fertilizer production. Because it can improve the efficiency of plants to absorb nutrients through the life activities of microorganisms contained in it. But compared with organic fertilizer manufacturing, it has a more complicated process. Besides fertilizer making, it is also essential to focus on microorganism adding. Then how to make biofertilizer smoothly? For this, there are various fertilizer machines for your choice, which can help you finish biofertilizer production of powder, granule and liquid easily and quickly.

What are the commonly used microorganisms in bio fertilizer making project?

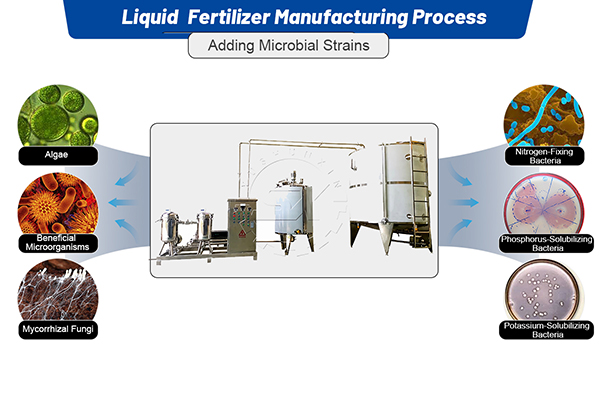

The use of microbial strains is the core of bio organic fertilizer preparation. In general, microorganisms are divided into two types: composting microbial inoculant and functional bacteria. And you need to add them in different stages:

Composting microbial inoculant

As the name suggests, composting microbial inoculant is widely used in biofertilizer composting process. It is beneficial for facilitating manure composting and eliminating the odor of animal manure. And commonly, this microbial agent is a kind of complex bacteria. Including photosynthetic bacteria, lactic acid bacteria, yeast, actinomycetes, penicillium, trichoderma, etc.

Functional bacteria

But the functional bacteria is suitable to use after composting, because high temperature will kill it. It contains azotobacter, phosphobacteria, silicate bacteria, lactic acid bacteria, pseudomonas, actinomycetes, etc. They play different roles in bio fertilizer production. You can choose according to your needs.

When is it suitable to add functional bacteria in bio fertilizer making?

Which step is the best choice to add functional bacteria?

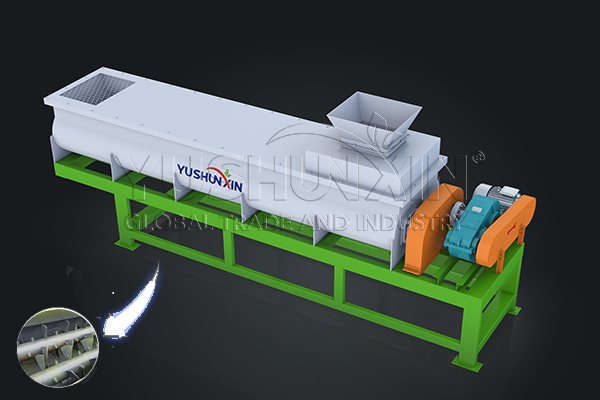

In this way, it can prevent functional bacteria from high temperature damaging. And microorganisms adding, we can offer you double shaft mixer for powder biofertilizer making and coating machine for quality biofertilizer granules production. They both have spray device, which can help you add bacterial agent precisely.

How to provide a suitable environment for functional bacteria living?

If you want to produce high quality bio fertilizer, you also need to focus on the adjustment of temperature, moisture content, organic matter content and C/N ratio.

When the temperature reaches 60 ℃, 80% of the microorganisms will die. So after adding functional bacteria, the temperature of bio fertilizer materials should be controlled below 50℃.

Moisture is essential for microbial activity. So in the process of biofertilizer manufacturing, it is necessary to adjust to a proper level. Which is suitable for biofertilizer pellets making and can support the reproduction of microorganisms.

They also play important roles in functional bacteria living. For biofertilizer making, you’d better control the organic matter content between 50%-70% and C/N ratio at 30-35:1.

TOP 2 Bio fertilizer production lines in YUSHUNXIN

In general, there are two types of biofertilizer organic production lines that are commonly used in biofertilizer manufacturing plants.

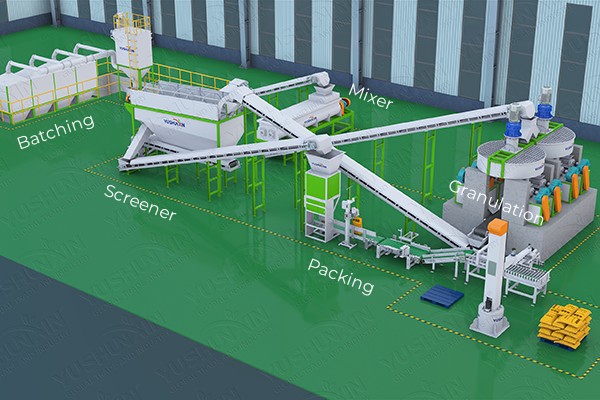

Powdery biofertilizer manufacturing plan

If you need a low cost and simple process bio fertilizer making plan, you can buy our powdery bio organic fertilizer manufacturing line. Only composting machine, material feeder, crusher, mixer, screener and packing equipment, it can make quality bio fertilizer from organic waste for you.

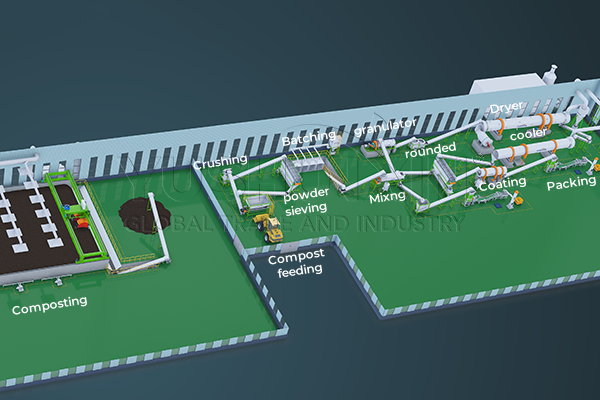

Bio fertilizer granules production line

In addition, we also design fertilizer granulation line for biofertilizer pellet preparation. It will process composted material with crushing, mixing, granulation, screening, drying, cooling, coating and packing. Which help you make biofertilizer with balanced nutrients, longer storage time and better fertilizer effect.

Can the lines make bio compound fertilizer?

Of course. The powder and granular bio fertilizer making line can not only make organic biofertilizer but produce bio compound fertilizer for you. Only need to use humus organic material as bacterial carrier. Like peat, weathered coal, lignite, etc

What you need to do for better bio fertilizer composting?

In general, composting plays an important role in biofertilizer production. Because it can eliminate harmful substances and unpleasant odors of manure. Then how to start bio fertilizer fermentation better? Besides adding composting microbial inoculant, using a professional compost machine is your optimal option. It can turn materials regularly to supply oxygen and dissipate excessive heat. They are beneficial for better aerobic fermentation of biofertilizer. There are two compost turners that are very popular with biofertilizer suppliers now.

Windrow compost turner for small scale bio fertilizer fermentation

Then if you want to make biofertilizer compost fertilizer in a small scale, we also can offer you windrow compost turner. It can process compost piles of a width of 2.4-3 m and a height of 0.6-1.5 m. That is, it can help you process 500-1500 ㎡ of biofertilizer per hour. In addition, it also has a characteristic of easy operation. Even a semi-skilled worker can drive to compost the large amounts of fertilizer windrows on the flat ground easily.

How to make bio fertilizer into granules?

In order to make biofertilizer easier to transport, store and sell, most biofertilizer plants prefer to process biofertilizer into pellets. For this, it is essential to buy suitable granulation equipment. Here, we recommend you choose the following two organic fertilizer granulation machines. New type organic fertilizer granulator or rotary drum pelletizer.

New type granulation machine for small scale bio fertilizer granulation

Provided you need a small scale granulation machine for biofertilizer processing, new type organic fertilizer granulator is an excellent choice for you. It has a capacity of 1-8 t/h, which can fully meet your requirements of small scale capacity. In addition, because it mainly relies on mechanical force of stirring teeth rotation to granulate bio fertilizer compost. The final biofertilizer pellets have a higher hardness, which makes it more convenient for use.

Rotary drum pelletizer for large scale bio fertilizer particles manufacturing

When it comes to large scale biofertilizer granulation, we recommend you choose rotary drum pelletizer. Using it, you can even prepare 30 tons of bio fertilizer granules an hour. Moreover, with designs of rubber lining, clean holes and lift plates, it can produce biofertilizer with less sticking. That is, longer service, less material waste and higher granule making efficiency.

What can you do to upgrade your bio fertilizer making line?

If you want to make bio fertilizer in a simple manner, you only need to buy compost machine and granulation equipment. However, provided you plan to upgrade this biofertilizer manufacturing system, you also need to purchase machines as follows:

Manure dewatering equipment

Dehydrator can help you reduce the moisture content of manure to 30%-50% quickly. So you can start bio fertilizer compost making better.

Batching machine

Batching equipment can feed raw materials according to your requirements. Therefore, you can produce biofertilizer according to local farming conditions.

Crusher

Crusher is widely used in grinding agglomerated into fine powder. It is beneficial for the composting and granulation of biofertilizer production.

Mixer

Mixer can help you mix various raw materials evenly. Which is the secret of preparing bio fertilizer with a balanced nutrient content.

Screener

Compost screener is designed to separate the biofertilizer you need from the unqualified. Then you can return the unqualified products to reprocess.

Dryer and cooler

Dryer and cooler can further remove excessive moisture from your granular bio fertilizer. So it can meet the international requirements of bio fertilizer water content (14%).

Coating equipment

Coating machine can add a protective film to your bio fertilizer pellets. Which can prevent sticking and nutrient loss.

Packaging machine

This is the final step of biofertilizer making. After processing with our automatic bagging machine, your can transport, store and sell your bio fertilizer in an easier way.

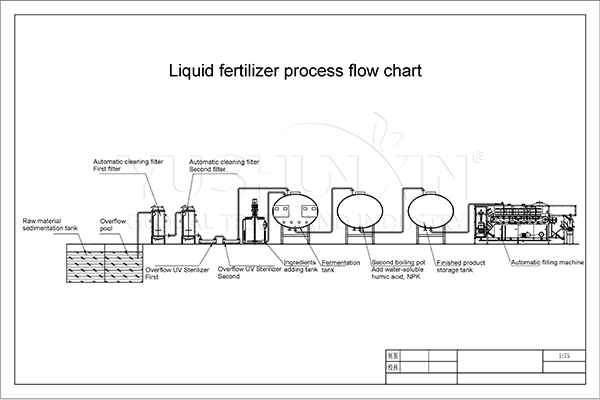

Is there liquid biofertilizer production technology?

The answer is yes. For liquid bio fertilizer manufacturing, we also can offer you suitable liquid fertilizer machines. Including manure dewatering machine, activated carbon filters, UV disinfection, bacteria or NPK material batching tank, fermentation tank, etc. They all use stainless steel as material, which can withstand the liquid erosion. Also, it can make liquid bio fertilizer from both organic and chemical materials.

Are These Solutions Only for Preparing Organic Bio Fertilizer?

The main application of the above systems is indeed to produce organic biofertilizer. Blending beneficial microorganisms with organic waste compost or carrier materials and then processed into powder, liquid, or granules. They can fully meet your requirements of cow dung fertilizer production, chicken poop fertilizer manufacturing, pig manure fertilizer making… with beneficial microorganisms.

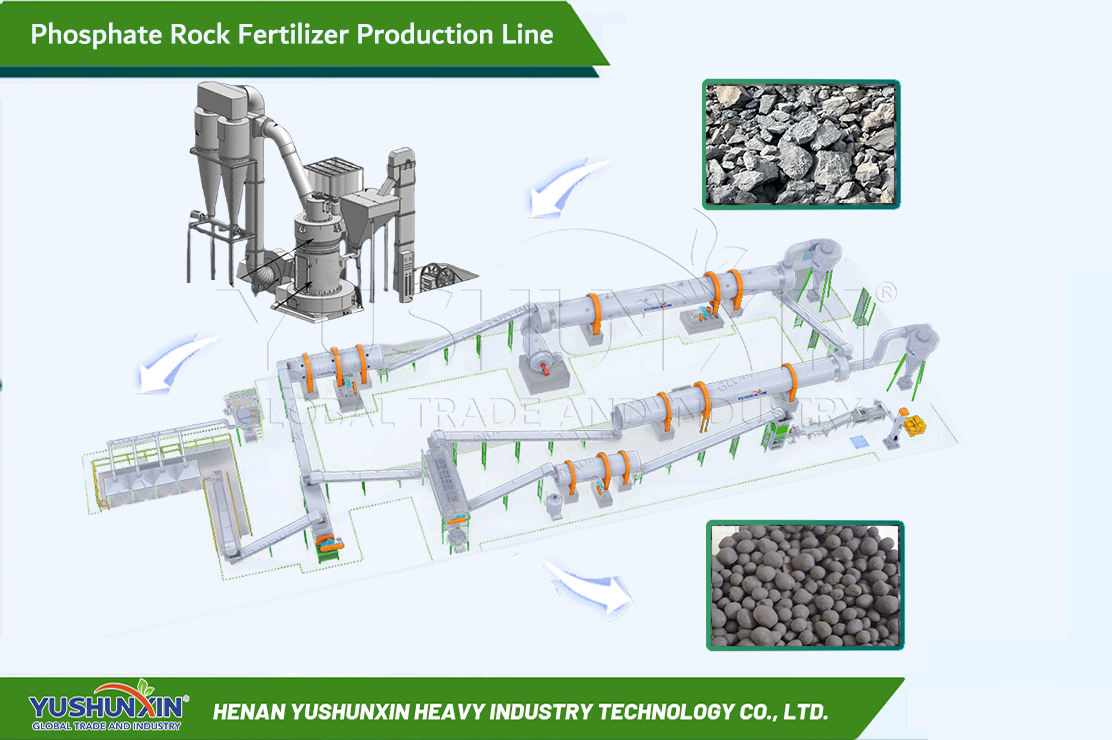

While organic biofertilizer making is a primary choice for manufacturers, the above bio fertilizer production plan are also be integrated with chemical fertilizer production processes. Including NPK fertilizer making, bulk blending fertilizer production, phosphate rock fertilizer manufacturing, etc. YUSHUUNXIN can offer you customized compound biofertilizer making plan!

Where are your established biofertilizer production plants?

Over past 20 years, we have help many fertilizer manufacturers start their plants to make bio fertilizer successfully. Such as 60 TPD biofertilizer making in United States, organic biofertilizer plant setup in Pakistan, 20,000 annual biofertilizer granule making in India, etc. If you want to visit the biacterial fertilizer making line operation, welcome to visit our factory in Xingyang City, ZhengZhou City, Henan Province, China.

If you have any other requirements for how to make bio fertilizer, welcome to contact us immediately. There is customeized bacterial fertilizer manufacturing plan design for you. In addition, YUSHUNXIN also can offer you many other fertilizer production business plans. Such as biochar fertilizer production line, NPK fertilizer making system, 100,000 t/y organic fertilizer granulation lines, etc