What can crushing machine do for quality fertilizer making?

Whether you want to make organic fertilizer or start a NPK fertilizer production project, fertilizer crushing machine is necessary. Why? Because it can crush your fertilizer materials into fine powder quickly and easily. This is greatly beneficial for your fertilizer manufacturing in the following three aspects:

Speed up organic fertilizer composting

In general, composting plays an important role in organic fertilizer making. Because it is a process of killing harmful substances in organic waste. But this process will take a long time, about 20-25 days, even if you use fertilizer composting machines. Do you want to speed up organic fertilizer composting? Processing organic waste with fertilizer crushing machine is an ideal choice. Because it can crush organic waste cakes into fine powder, which has a larger contact area with oxygen. So you can complete fertilizer aerobic fermentation more smoothly and decompose organic waste quickly.

Make better organic / NPK fertilizer pellets

In addition, if you plan to prepare fertilizer into granules, it is advisable to use crushing equipment before granulation. Whether you want to prepare organic fertilizer pellets or NPK fertilizer granulation. Why? Because compared with large particle size, powdery fertilizer is easier to form into organic / NPK compound fertilizer pellets you need. What’s more, the finer the powder, the more smooth the fertilizer granule appearance, the higher the competitiveness.

Reduce raw materials waste

Then after fertilizer granulation, you will find that there are some fertilizer granules that have a size which is larger or smaller than you require. How to treat them? Discard directly? No, what a waste! You can return them for re-granulation. But before this, you need to grind these unqualified fertilizer particles into powder again by suitable fertilizer crushing machine. In this way, there is nearly no material waste in your fertilizer production process.

How to choose commercial compost pulverizer for your organic fertilizer making?

As mentioned above, both before and after composting, it is advisable to use fertilizer crushers. However, how to purchase suitable compost pulverizer for your commercial organic fertilizer manufacturing? Generally, you need to pay attention to material moisture content, capacity and types. According to this, we design commercial compost grinders as follows:

High moisture chicken manure compost crusher

Large scale cow dung compost grinder

Then provided we plan to dispose of cow manure into compost fertilizer powder, which fertilizer crushing machine is more suitable for it? A cow usually generates 35 kg of manure a day, which is far more than chicken. So at that time, you may need a manure shredder with a larger capacity. Here, you can choose the new type vertical crusher. Its largest output can reach 15 t/h and the inlet size is 650×450 mm.

Is it also suitable for high moisture manure fertilizer processing? Of course. This vertical fertilizer crusher is also designed without screens. And it mainly relies on crushing blades to turn cow manure compost into fine powdery fertilizer.

Compost straw pulverizing equipment

Wood waste crusher

What equipment can be used for crushing chemical fertilizer?

Besides organic fertilizer making, crushing equipment also plays an important role in compound fertilizer making, especially NPK fertilizer manufacturing. In SX, you can purchase the following chemical fertilizer shredding machines:

Urea crushing machine for sale

Urea crusher is a typical equipment for single chemical fertilizer powder making. It mainly relies on the gap between the high speed rotating roller and the concave plate to cut and grind the chemical material. So even materials with high hardness, such as ammonium, diammonium and urea, this equipment also can crush them into fine powder. And the smaller the gap, the smaller the final powder particle size.

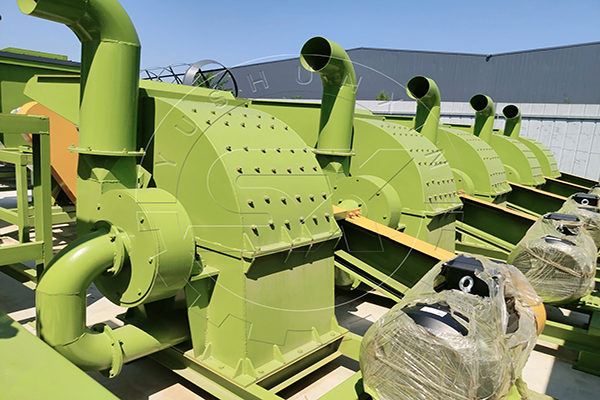

Cage grinder

Are there other crushers suitable for chemical fertilizer processing? Cage fertilizer crushing machine is an excellent choice for you. It belongs to the medium-sized horizontal fertilizer crushing machine. And it can produce 4-10 tons of chemical fertilizer powder per hour. In addition, this machine is designed according to the principle of impact breaking. The inside and outside two sets of cage bars rotate in the opposite direction at high speed. Then the materials will be crushed by the impact of the cage bar when though the two sets of cages. So it is the ideal tool for compound fertilizer crushing.

Is there equipment for chemical rock breaking?

Of course. Provided you plan to make chemical fertilizer making with ore or rocks (like SSP fertilizer manufacturing), you can use Raymond mill to break down them into powder. During work, Raymond mill mainly relies on internal grinding rollers and grinding rings to crush materials. After feeding ore chips into the pulverizer, the material dipper will send the material between the grinding roller and the grinding ring. At the same time, due to the centrifugal force from rotation, the grinding roller swings outward and presses against the grinding ring. So the materials between them will be crushed into powder materials quickly.

What materials can Raymond mill process?

Raymond mill is widely used in various materials crushing. Such as activated carbon, coal ore, charcoal blocks, limestone, lime, graphite, bentonite clay, calcite, talc, marble, dolomite, fluorite, phosphate rock, gypsum, etc. In general, it can make them into powder material with a granularity of 80-800 meshes.

Which fertilizer pulverizing machine is suitable for returned materials crushing?

From the above introduction, we know that returned materials crushing is also essential for fertilizer manufacturing. Whether it is organic fertilizer production or compound fertilizer making. Then which fertilizer crushing machine is the best choice for returned materials shredding? It is chain crusher. There are two reasons.

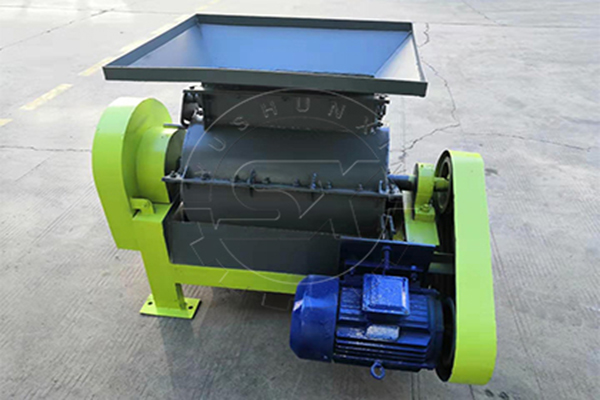

How to shred other solid waste?

In addition to the above animal manure waste and agricultural residues, there is many other solid waste you may want to shred. Is there suitable crushing equipment? Here, we recommend you buy a double shaft shredder. It can help you crush wood, coconut shell, other nutshells, metal, tires, polystyrene boxes, etc. With stainless steel crushing blades and shaft design, it can break down the material with a high hardness easily. Whether you want to treat biomass waste, domestic waste or industrial waste, double shaft shredder is an excellent choice.

If you need other equipment for organic and compound fertilizer production, you can also contact us. Drying equipment, industrial dust collector, fertilizer pellets machine, packaging equipment, etc, all you can find from our company.