Fertilizer coating machine plays an important role in fertilizer production. It can help you make various organic fertilizers and compound fertilizers you need. Including colored, nutritious and slow release fertilizer granules. Then, where to buy a quality drum coating machine for your fertilizer manufacturing? SX, as a professional fertilizer equipment manufacturer, can provide you with various coaters for your choice. And the coating machine price must be favourable.

What type of fertilizer coating machine can you choose in SX?

According to different fertilizer making conditions, you may need different types of fertilizer pellet coating machines. For example, in terms of fertilizer types, you need an organic fertilizer coating machine or compound fertilizer coater. In capacity respect, you can buy a large scale drum coater or small scale. Finally, automatic coating equipment is the secret of preparing fertilizer pellets quickly. But don’t worry, SX drum coating machine can meet all the requirements above.

For compound NPK fertilizer pellets processing, you need equipment with high corrosion resistance. For this, our fertilizer granule coating machine especially adopts high strength carbon steel as manufacturing material. In addition, there are angle irons inside the drum, which can greatly reduce the possibility of materials sticking. Then if you need, we can provide you with stainless steel or rubber lining adding service, which can further improve the erosion resistance of coater. So it has a long service life and even processes a large amount of urea, SSP, DAP, MOP, etc.

How does drum fertilizer coating equipment work to process fertilizer pellets?

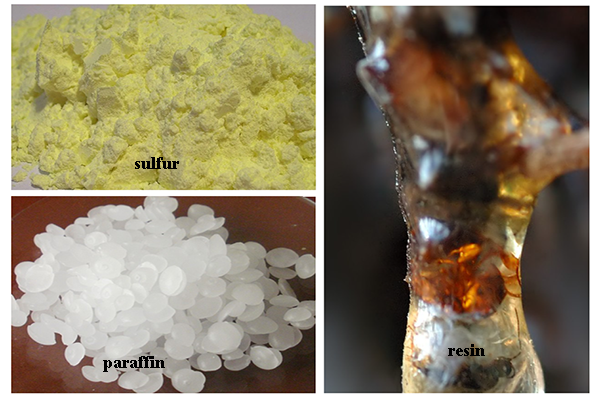

On the whole, fertilizer coating machine mainly makes use of powder or liquid materials to coat pellets to improve your fertilizer quality. After finished granules enter into drum coating machine, the inside spraying system will sprinkle coating materials you prepare. Then under the action of drum rotation, fertilizer granules will roll, so that the coating raw materials can evenly cover your organic & compound fertilizer granules. Then the machine will discharge coated fertilizer pellets to the next process.

How much does the drum coating machine cost?

Besides fertilizer coating machine, SX can also provide you with many other machines for organic or chemical fertilizer production. Including composting machine, crusher, granulator, screening equipment, packaging scale, etc. If you are interested in them, welcome to contact us immediately.