Why you need batching machine in fertilizer making process?

In general, fertilizer batching equipment plays an important role in quality fertilizer production. Even it is the first step of NPK compound fertilizer manufacturing. Why? Because it can bring you benefits in the following two aspects:

Filter waste

When you produce organic fertilizer, you will find that there still is some waste in material after fertilizer composting. Such as stones, branches, etc. Leaving them alone will seriously affect fertilizer quality, especially when you prepare granular organic fertilizer. At that time, you can use our batching machine which has a filter mesh. It can remove the waste from raw materials to improve the purity of your fertilizer.

Improve the accuracy of raw material ratio

In order to produce fertilizer with richer nutrients, we usually use a variety of materials. But if you want to prepare better organic fertilizer and compound fertilizer, only add them is not enough. You must deliver materials in a strict accordance with the required ratio. Batching machine is designed for this. It adopts electronic weighing scale, which has a high quantitative precision.

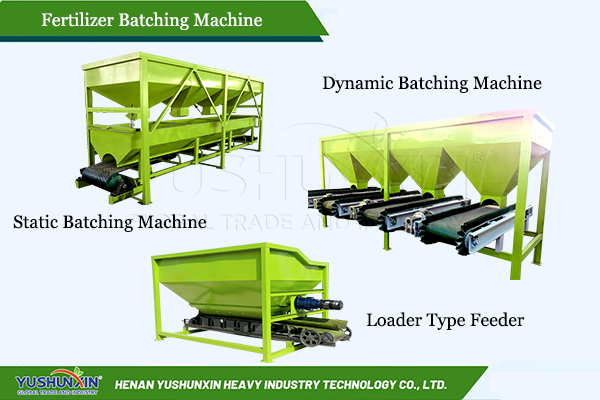

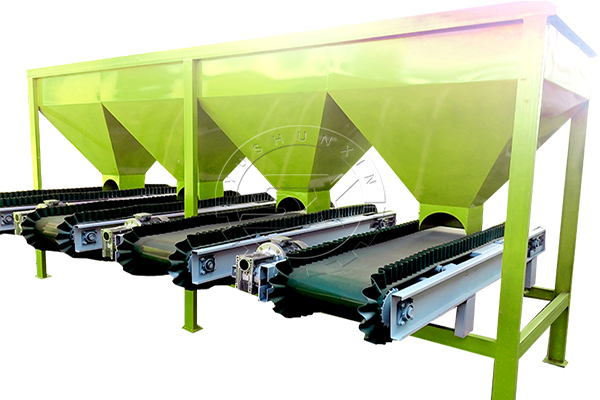

Which type of fertilizer batching machine is suitable for you?

After deciding to purchase a batching machine for your fertilizer production, there is an item you must pay attention to. It is which type of fertilizer batching machine is suitable for you? There are some tips for your reference.

How does fertilizer batching equipment work to help you produce better fertilizer?

No matter what device you want to buy, it is always essential to learn how it works. Of course, the same is true of fertilizer batching equipment purchasing. Then what is the working principle of SX fertilizer batching machine? Why can it deliver materials in a strict accordance with the required ratio?

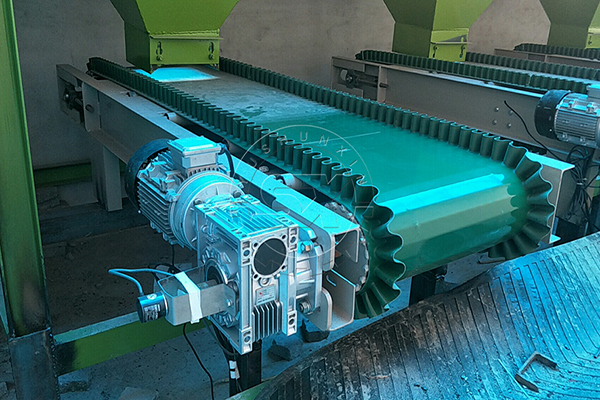

Can batching machine process high moisture fertilizer materials without blocking?

If using high moisture material in fertilizer manufacturing process, can batching equipment discharge it without blocking? This is an item most fertilizer manufacturers focus on when using fertilizer batching equipment. But don’t worry,as a professional fertilizer machine factory, SX especially upgrade the design of our batching machine in the following aspects:

Besides fertilizer batching equipment, SX can also provide you many other machines, which are beneficial for fertilizer making. Including fertilizer composting machine, granule making machine, crusher, mixer, drying machine, etc. Welcome to contact us anytime!