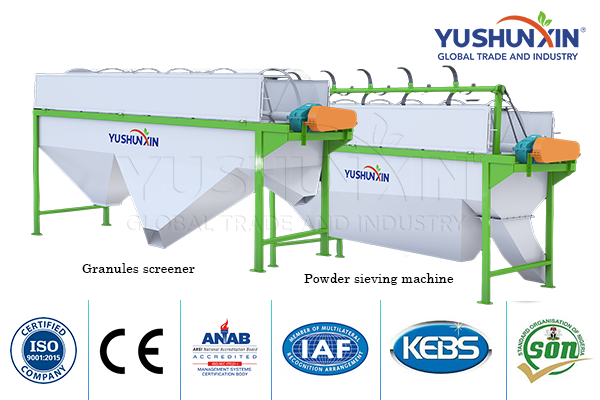

Compost screen machine plays an important role in organic fertilizer making process. Whether powdery organic fertilizer making or granular organic fertilizer production. Because it can sieve out fertilizer you want to produce. This is greatly beneficial for quality organic fertilizer manufacturing. Here, SX compost screen machine is an ideal choice for you. According to the requirements of fertilizer manufacturers, we especially design powder and granule screening machines for your choice. If you have any other requirements, you can contact us for customization.

What can compost screen machine do for quality fertilizer making?

If you want to produce quality fertilizer from compost, it is essential to process compost with screening equipment. Why? What can it do for the manufacturing of your fertilizer?

Improving the purity of your fertilizer

In general, there still is much impurities in material after fertilizer composting. Such as small stones, cigarette butts, etc. This will affect the quality of your fertilizer. But our rotary screening machine can separate fertilizer from waste. So you can turn compost into fertilizer with a higher purity, which means higher competitiveness on the market.

Reducing materials waste in fertilizer making

Moreover, our fertilizer screener also can separate qualified fertilizer from the unqualified. Then you can return unqualified compost fertilizer to reprocess while sending qualified compost to further process it into organic fertilizer. That is, you can nearly turn all compost materials into organic fertilizer without waste!

How does rotary screening machine work to sieve your fertilizer?

After entering the rotary screening equipment, the compost material will turn and roll under the action of sieve mesh rotation. In this way, the compost fertilizer which meets the required size can pass through the sieve holes and enter the next organic fertilizer making process. But the unqualified fertilizer will be separated from and discharged through the end of the screener.

Will the material clog the screen holes in the production of fertilizer? Of course not. As mentioned above, compost will roll continuously because of the rotation and inclination of the screen mesh. So the material stuck in the sieve hole will be ejected, which will prevent the sieve hole from blocking.

What is the difference between powder and granule compost screen machines?

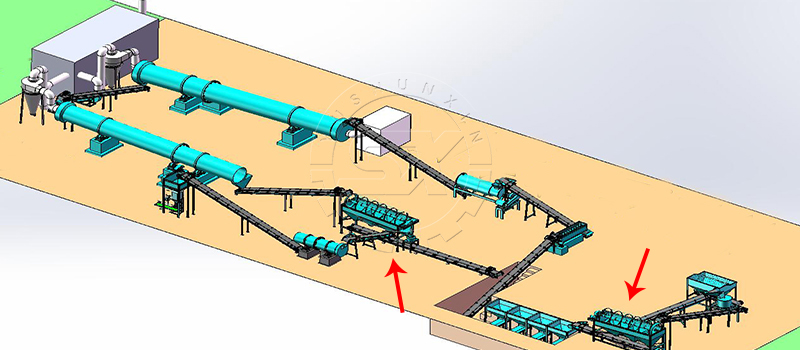

In the process of organic fertilizer manufacturing, in order to produce quality fertilizer, we recommend you screen compost twice. One is after crushing compost into powder and another is after turning it into pellets. According to different requirements of them, we especially design powder compost screen equipment and granule fertilizer screener. Then what is the difference between them?

However, they also have many similarities. For example, they both have a screening capacity of 1-20 t/h. In addition, they are both widely applicable to sieving various solid materials with particle size less than 300 mm. What’s more, they also have characteristics of high screening efficiency, low noise, small amount of dust, long service life, less maintenance and convenient maintenance.

Why not screen fertilizer pellets after drying and cooling?

In the process of fertilizer pellet making, we generally recommend you design compost granule screening equipment after granulation and before drying and cooling. But why not screen fertilizer pellets after drying and cooling? There are two reasons:

Other things most fertilizer manufacturers want to know

Galvanized steel, which has high erosion resistance. So its service life will be longer.

Besides, there are many other machines for fertilizer processing. Such as fertilizer composting machine, drying machine, packaging scale, granule making equipment, etc. Welcome to contact us now for your fertilizer machine buying.