When you want to make chemical fertilizer, you need to pay attention to aspects. Including materials, technologies and equipment and cost. Finally, you need to ensure the safety of your chemical fertilizer plant. YUSHUNXIN, as a professional fertilizer equipment manufacturer, not only can provide you with suitable chemical fertilizer production line, but also offer you many other tips for better compound fertilizer manufacturing. Such as materials choosing, cost saving, etc. If you have any other requirements, you can also contact us for the best solutions immediately.

What raw materials are commonly used in chemical fertilizers production line?

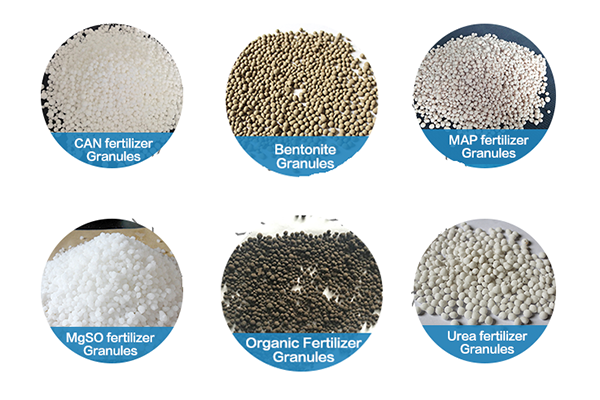

Material choosing plays an important role in compound fertilizer manufacturing. Because it is closely related to what kind of complex fertilizer you prepare and which chemical fertilizer making line you can choose. In general, you can consider the materials for compound fertilizer preparation from two respects:

Chemical materials types

To a certain extent, your chemical materials types determine the produced final fertilizer type. So

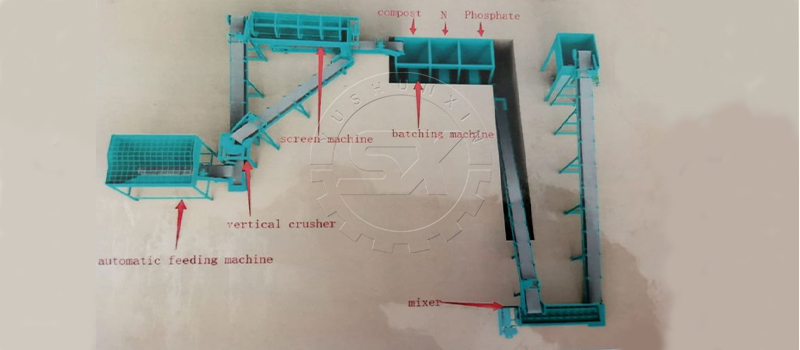

Raw materials shape

Top 4 complex fertilizer making technologies for your choice

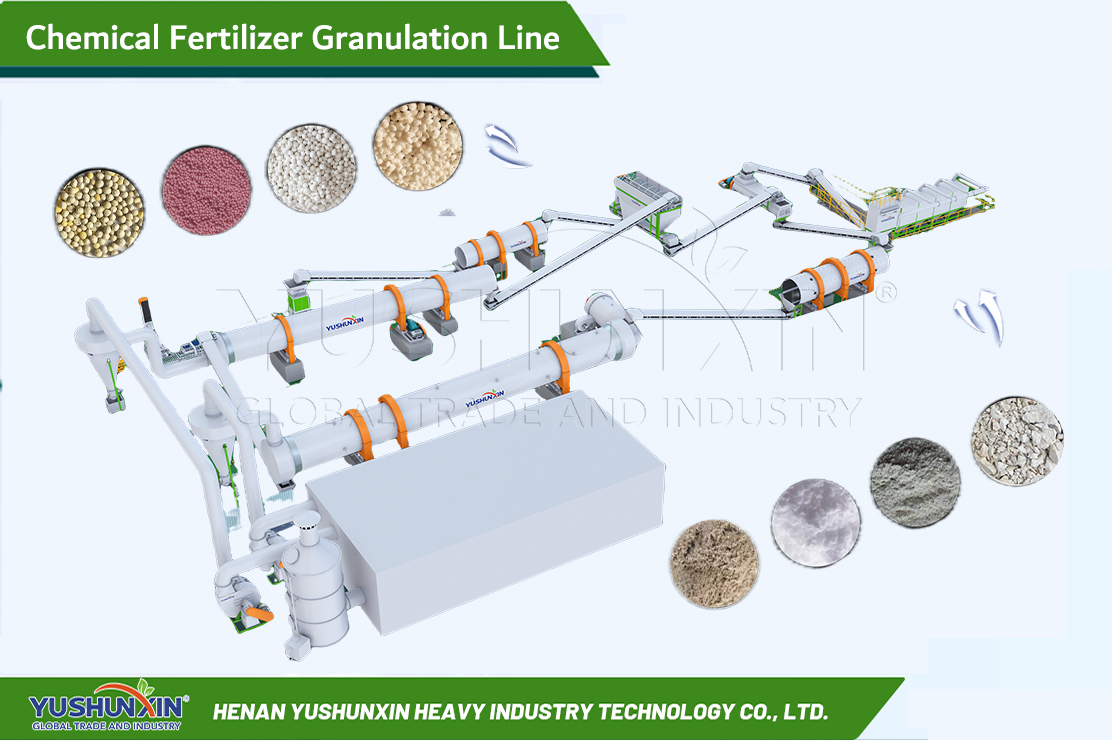

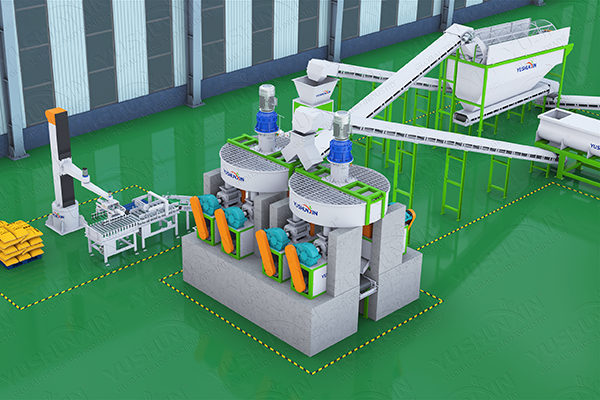

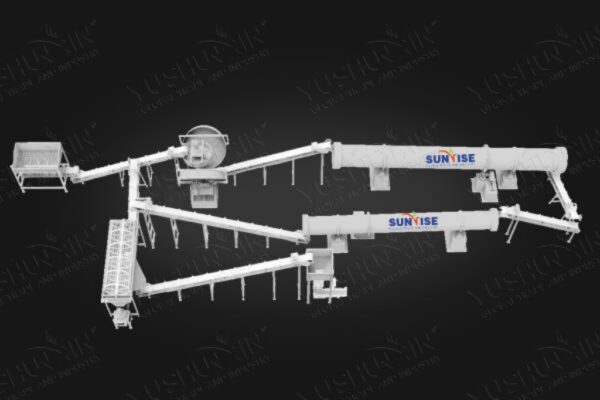

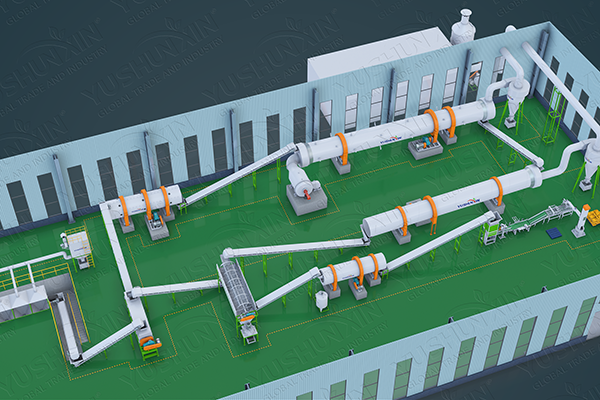

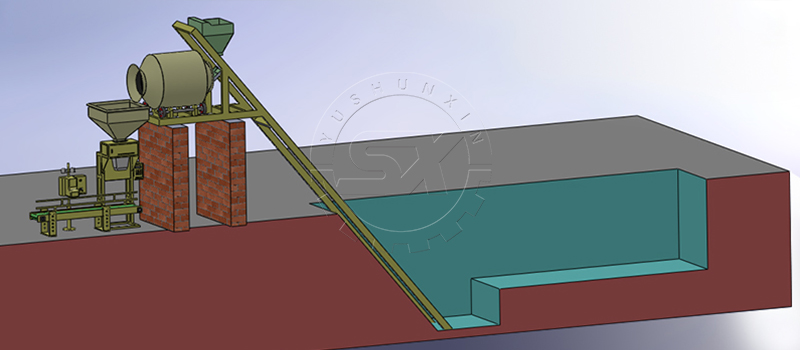

According to your raw material conditions, SX designs different chemical fertilizer production lines for your choice.

What is the cost of chemical fertilizer manufacturing?

During chemical fertilizer production plant setup, cost is an item you must focus on. According to your budget for complex fertilizer making, YUSHUNXIN can offer you suitable business plan and equipment. Generally, the cost of compound fertilizer manufacturing consists of equipment purchasing, area preparation, labor force and energy consumption.

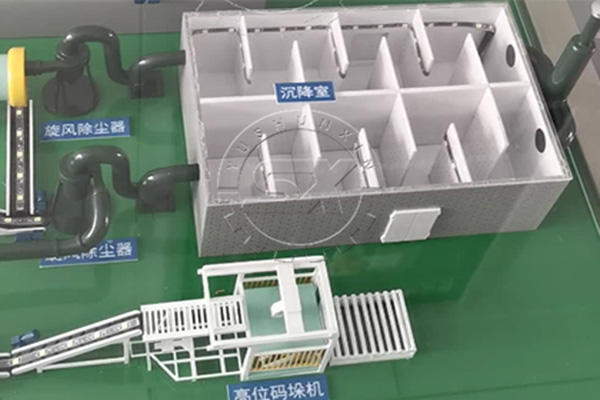

How to ensure the safety and environmental friendly of the chemical fertilizer production?

Lastest compound fertilizer production machines cases

In addition, there are some lastest established chemical fertilizer plants with YUSHUNXIN machines for your reference.They contain not only BB fertilizer making in Sri Lanka, NPK granulation line in Indonesia, but also phosphate fertilizer making in Morocco, bentonite granule production in Colombia, etc.

Besides, there are also various organic fertilizer making plans, biofertilizer production lines, biochar fertilizer systems for you. Ranging from 1 t/h to 30 t/h, with materials from cow dung to chicken poop, costs from $10,000 t0 $500,000, etc. Come to see them immediately!