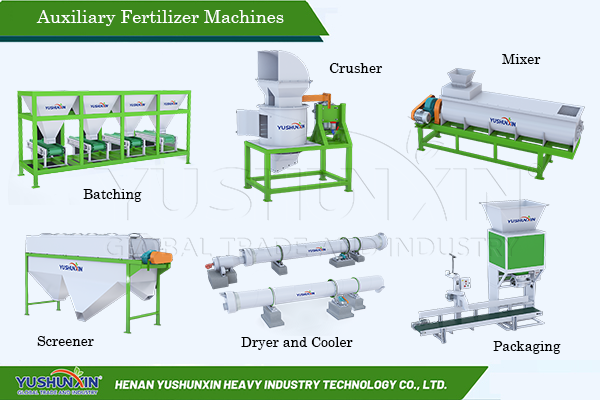

Auxiliary facilities for fertilizer production are vital components that enhance the efficiency and quality of fertilizer manufacturing. These include material handling equipment like conveyors and feeders for transporting raw materials, crushers and grinders for size reduction, mixers for blending ingredients, and screening machines to ensure uniform particle size. Additionally, precise packaging machine for your commercial fertilizer production. These fertilizer machines work in tandem with compost machine and fertrilizer granulators, ensuring an effective production process of high-quality organic and compound fertilizers.

Fertilizer batching auciliary facilities

Fertilizer batching equipment is designed for the precise feeding of various materials and ingredients to ensure you can make fertilizer you require. Especially when you make compound NPK fertilizer.

Utilizing sophisticated control systems, this machinery ensures accuracy and consistency in the proportions of each input, resulting in highly efficient fertilizer formulations. Equipment varieties range from loader type feeder to automatic dynamic batching machine, catering to operations of different scales and complexities. These systems often include features such as material bins, belt conveyors, electronic scales. With the integration of smart technology and data analytics, modern fertilizer-batching equipment can adapt to real-time feedback, further optimizing the manufacturing process of organic and chemical fertilizers.

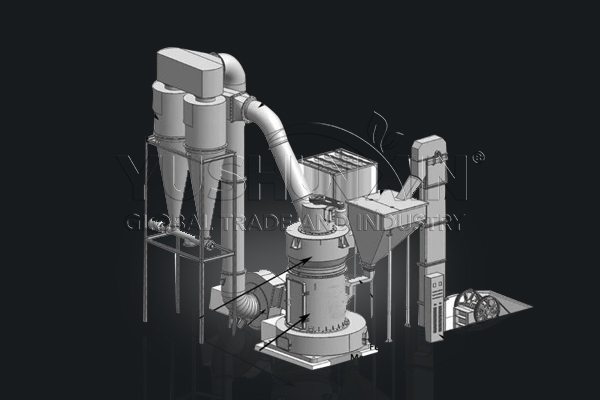

Fertilizer-crushing equipment

Whether you plan to make powdery fertilizer or granular fertilizer, fertilizer-crushing equipment is important in auxiliary facilities. It will break down raw materials into finer particles.

For one thing, because of smaller particle size, produced fertilizer can offer nutrients to crops and plants effectively. Namely, grinding fertilizer can greatly improve the efficiency and effectiveness of the fertilizer you make. For another, it can help you make organic and compound fertilizer into granules quickly. The finer the fertilizer powder, the faster the fertilizer production and the better the granules appearance.The fertilizer grinding machine includes various types in YUSHUNXIN. Such as wet material crusher, vertical grinder, straw crushing machine, wood waste grinder, chemical material crusher, mine shredder, etc. Each tailored to accommodate your different materials and crushing requirements.

industrial mixer for fertilizers production

An industrial fertilizer mixer can ensuring that raw materials are thoroughly combined to produce fertilizer with balanced nutrient content. These robust machines can fully meet your rigorous demands of blending a variety of ingredients, including chemical powders, granules, and liquids.

Equipped with powerful agitators or paddles, industrial fertilizer mixers facilitate the even mixing of nitrogen, phosphorus, potassium, and other micronutrients.Which guarantees the even application of nutrients when applied to fields. Industrial mixers come in different configurations, such as basic horinzontal mixer, small sclae single ribbon blender, effective double shaft mixer, economical vertical mixer, special BB fertilizer mixer, etc. Advanced features of our fertilizer blending machines include automation controls, corrosion-resistant alloy materials, etc. These can ensure the mixer reliability, efficiency, and a long service life in the demanding environment of fertilizer production.

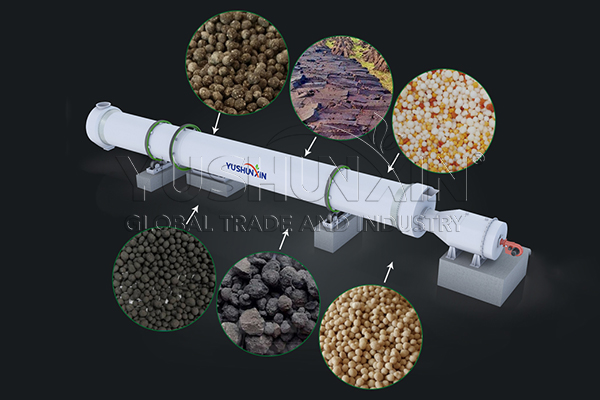

Rotary dryer and coller application of fertilizer manufacturing

The rotary dryer and cooler provide an efficient solution for drying finished organic and chemical fertilizer. It can dry your fertilizer powder or granules into 10% and even 3% moisture content. So, the fertilizers are easier to transport, store and use.

This essential equipment operates by injeting hot air in rotary drum. The 200 ℃ hot air can create a 60℃ drying environment for your fertilizer making, causing moisture evaporation from the fertilizer quickly. In addiotion, the material lifting plantes and consistent rotation deisgns ensures uniform drying and prevents agglomeration.But how to reduce the fertilizer temperature after drying? After hot air drying, the fertilizer you make has a temperature of 30℃ -40℃ , which means you cannot pack it immediately. Therefore, many fertilizer manufacturers choose to add a rotary cooler after drying in their fertilizer plant.

The fertilizer drying system is highly versatile. There are various models for your choice according to drying times, temperatures, and type of fertilizers – from simple manure compost to complex NPK (Nitrogen, Phosphorus, and Potassium) mixture. Their robust design and scalable nature make them suitable for both small and large-scale fertilizer production operations. By optimizing the moisture content of fertilizers, rotary dryers and coolers not only enhance the quality and efficacy of the final fertilizer products but also improve the overall efficiency and sustainability of you fertilizer manufacturing process.

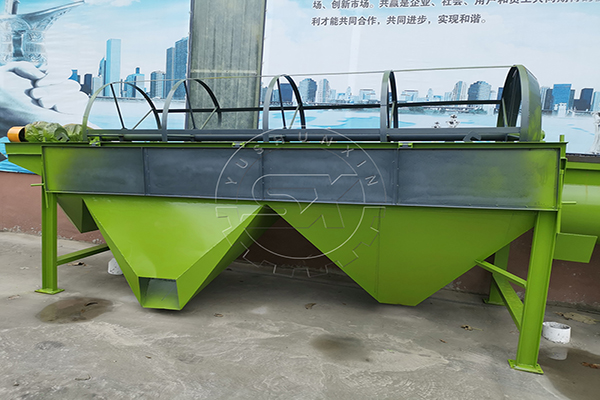

Screener machine in organic & compound fertilizer production

A fertilizer screening machine is designed to separate unqualified granules from the finished product and return them for reprocessing. One the one hand, ensuring the uniformity and quality of your fertilizer making. On the other hand, this is benecifial for improving raw material utilization (99%) and reduce the waste.

This machine typically involves powder or granule fertilizer types. The former can remove stones and small waste from powdery fertilizer and reture the large agglomerates for reprocesing. The latter can sorts granules based on size, effectively segregating oversized or undersized fertilizer particles from the fertilizer granules specifications you need. The adaptability of the machine allows for its use in various stages of production and for different types of fertilizers. From organic compost to chemical fertilizer pellets manfuacturing. From 1t/h to 20 t/h.

Bagging system for auto fertilizer making

The bagging system for auto fertilizer making is a crucial component in the automated production line of fertilizers. It can streamline the your fertilizer packaging process for efficiency and accuracy. Besides high precise fertilizer bagging macine, it also has palletizer for quickly packing fertilizer in a large scale.

This system involves weighing, filling, and sealing bags with a predetermined amount of fertilizer. Our fertilizer packing machine integrates advanced sensors and control software to facilitate precision in the bagging operation, accommodating various bag sizes and types. From 5 kg/bag to 1 ton/bag. The system’s automation minimizes the need for manual labor, reducing the potential for human error and enhancing the speed of the your fertilizer packaging process. With the incorporation of palletizer, the bagged fertilizer can be easily storaged or shipment. The fertilizer bagging system is engineered to handle a wide array of fertilizer forms, including granulea and powder.

Manure dewatering machine – special auxiliary facilities for organic fertilizer production

In additon, there are some auxiliary facilities are especially manufactured for the production of organic fertilizer. Like manure dewatering machines.

The equipment has function of separating liquids from solids in animal waste, predominantly manure from livestock and poultry such as cows, pigs, and chickens. The separation process is essential in reducing the moisture content in organic waste, thereby making it more suitable for composting and further processing into high-quality organic fertilizer. The dewatering machine contains two types – screw press dehydrator for 50%-70% wet manure disposal and inclined-screen liquid solid seprarator for over 80% manure waste treament. Then, you can choose to make solid manure organic fetilizer and produce liquid organic fertilizer according to your needs.