If you plan to invest in fertilizer manufacturing in Indonesia, the following information is for your reference. What is the best fertilizer making project, top 3 fertilizer systems, operational fertilizer production plants, good fertilizer machine manufacturer, etc.

Why Invest in Fertilizer Manufacturing in Indonesia?

In Indonesia, there are a significant amount of organic waste generated. Such as chicken manure, cow dung, and other farm by-products, which contains rich nutrient that is beneficial for crops and plants growth. Making the organic waste into valuable fertilizer presents an excellent opportunity to reduce waste and environmental pollution.

At the same time, investing in fertilizer manufacturing can be highly profitable. As demand for agricultural products grows, the need for fertilizers continues to rise, particularly in a nation like Indonesia, where agriculture is a cornerstone of the economy. With the right technology, efficient production systems, and a solid market strategy, fertilizer manufacturing plants can generate substantial revenue by meeting the increasing demand from local farmers.

What Fertilizer Making Projects are worth investing in Indonesia?

According to feedback of the past Indonesian customer, there are 3 fertilizer production lines that are worth investing in:

Chicken Manure Organic Fertilizer Production Line

Indonesia’s poultry industry is vast, with millions of chickens raised for eggs and meat every year. But, this also mean that there are a large amount of chicken manure generated, which is an excellent resource for organic fertilizer production. Setting up a chicken manure fertilizer making line to dispose chicken poop into high-quality organic fertilizer can be a lucrative venture.

Cow Manure Organic Fertilizer Production Line

In addition, Indonesia also has a large cattle farming industry, which produces significant amounts of manure. If you are the owner of cow farms and finding a solution for cattle farm manure management, investing in cow manure organic fertilizer production lines is an ideal choice. It is not only beneficial for removing manure pollution quickly but also bring you high profits.

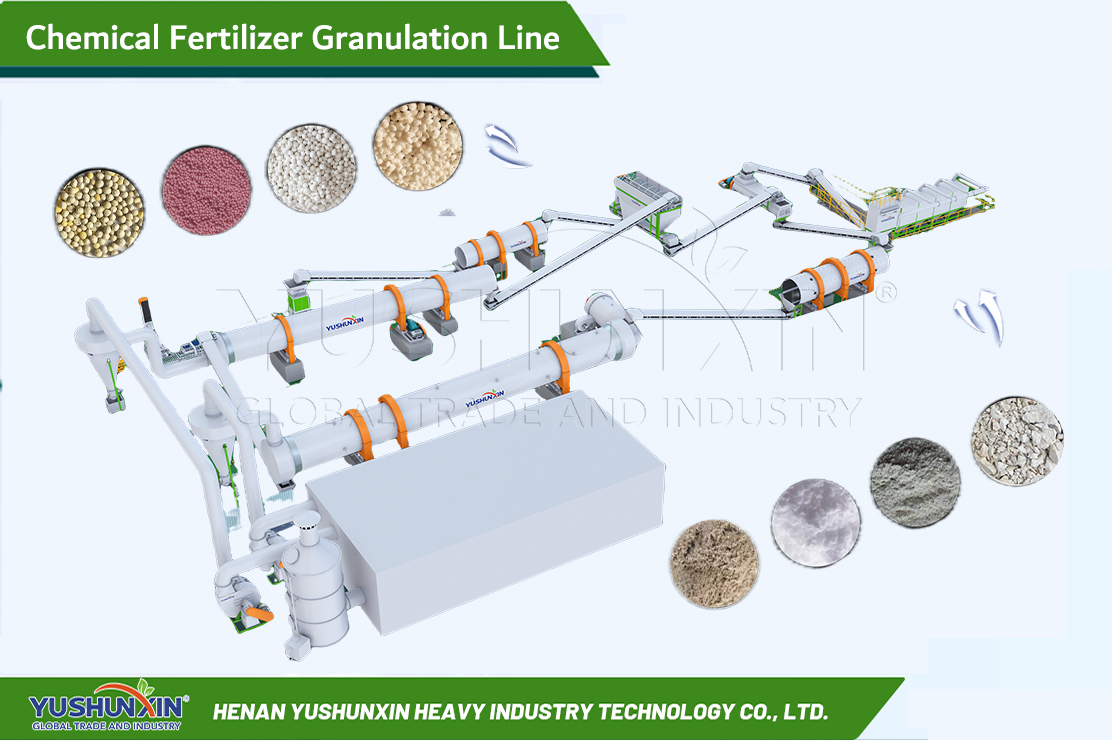

Compound Fertilizer Production Line

Then, you can also choose to setup a compound fertilizers plant in Indonesia. For one thing, there are enough phosphate rock and nitrogen fertilizer materials. For another, the compound fertilizer market is huge both at home and abroad. Moreover, the Indonesian government may provide various policy supports for domestic fertilizer production. Such as subsidies, tax incentives or trade protection measures.

Top 3 Fertilizer Production Systems in Indonesia

As for the fertilizer making machine purchasing, there are 3 types of fertilizer making lines are popular with Indonesian businesses.

Dehydration and composting system for animal farm Waste processing

One of the leading systems for fertilizer manufacturing in Indonesia is the dehydration and composting system. This system is especially popular for manage farm waste in a cost and the ground limited. By using fertilizer dewatering technology, organic manure waste can be processed into dry material. Then, industrial compost turner will decompose manure to eliminate pathogens, pest eggs and grass seed. Only 2 steps, you can prepare quality organic fertilizer. It is suitable for chicken farm waste disposal, cattle farm waste treatment and other organic waste treatment.

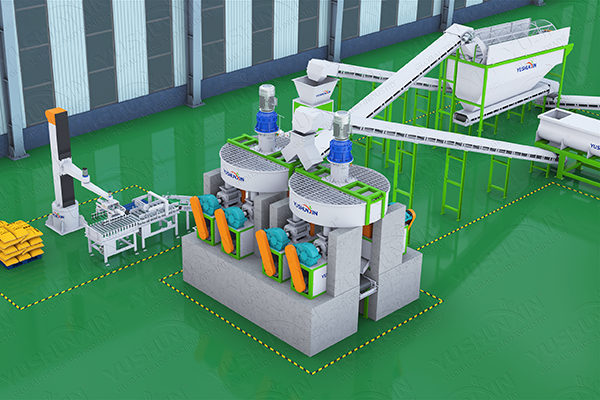

Organic Fertilizer Pellet Production Line

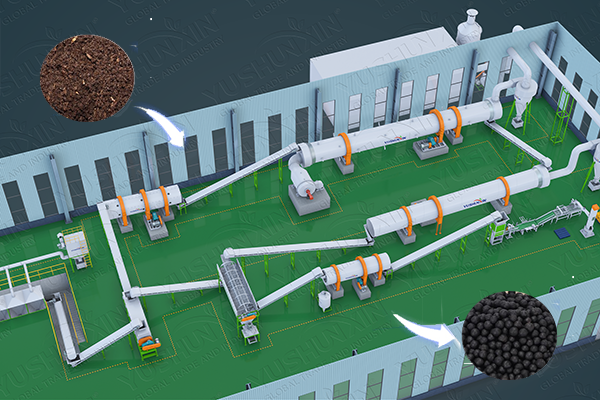

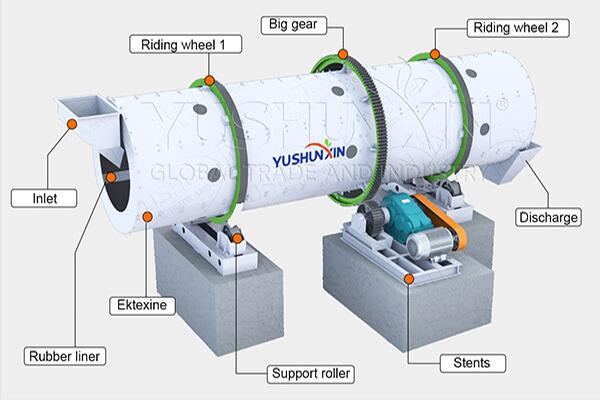

Next, it is the organic fertilizer granulation plan, which can help you make more profits. It is highly efficient for producing granular organic fertilizers from compost or manure. The best-selling one is rotary drum granulation system. This system can fully meet you requirement of making 3-6 mm organic fertilizer pellets in 1-30 t/h output in Indonesia.

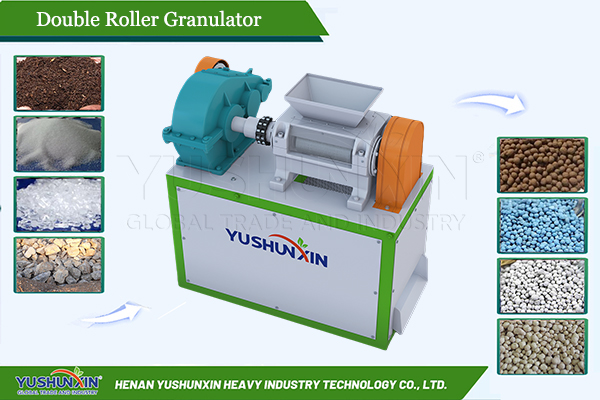

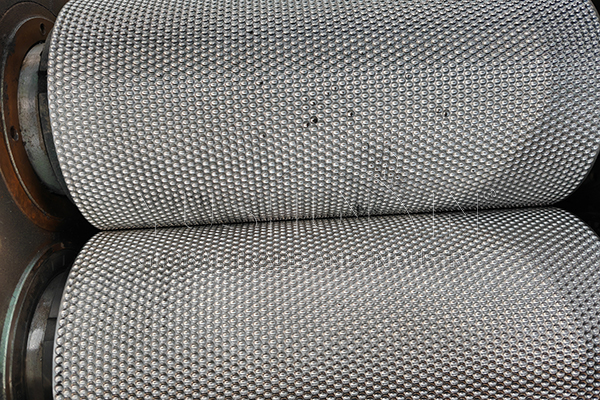

Double Roller Fertilizer Granulation Line

The double roller granulation line is a highly effective system for the fertilizer manufacturing, especially NPK compound fertilizers. This system can produces fertilizer granules without drying and cooling. Therefore, it has a minimal energy consumption and economical cost. However, the system can offer 2-10 mm fertilizer pellets in 1-20 t/h capacity. Therefore, it is an attractive investment option for fertilizer manufacturers in Indonesia.

2 Operational Fertilizer Manufacturing Plants in Indonesia

In the past more than 20 years, YUSHUNXIN had helped many fertilizer manufacturer setup their fertilizer making plants in Indonesia successfully. There are two case for example.

Compost and Biochar Granulation Plant in Indonesia

prepare carbon-based fertilizer. On 15 November 2023, a customer emailed us for solution to compost and biochar granule making in Indonesia. Here, this client wanted to make the mixture of compost and biochar into pellets, which is 3-5 mm size. In addition, there is a moisture content requirement of final biochar fertilizer granules – being 12% to 15%. Finally, the client bought a system that consists of a disc pelletizer and a rotary dryer. Its granulation rate can reach to 93%, but the pricing is only $24,282.

NPK Double Roller Granulation Line in Indonesia

On 12th March 2023, a customer inquired about NPK compound fertilizer manufacturing in Indonesia. He used Nitrogen (urea), Rock Phosphate, DAP/MAP (depend on Composition), KCL or ZK,clay, dolomite/calcium, etc as material, required a 120 tons per day capacity. So, we recommend the roller granulation line to him. Because of economical price.

Is There YUSHUNXIN machine Distributor of Fertilizer Manufacturing in Indonesia?

Yes, main YUSHUNXIN fertilizer factory is located in China. But we have oversea branch office in Indonesia.

- Address: Golf Island, JI. Pantai Indah Kapuk Ruko No.20 Blok J, Jakarta, Daerah Khusus Ibu Kota Jakarta 14470.

Welcome to contact us for discuss your fertilizer making business plan face to face!

Besides, we also have overseas offices in the United States, Russia, Algeria. If you need a fertilizer making system, come to contact us immediately.