How to dispose of the residues out of biogas project? This is what a customer from Kenya inquired about on April 5th, 2024. The client was from an energy company, which was currently working on a biogas project with Napier Grass and Cow dung. Now, in order to dispose of the biogas residue and expand the business scale, they planned to invest in setting up an organic fertilizer production line. According to the requirements of the Kenyan customer, we sent him a 50 TPD compost pelleting machine system.The following are the specific details of our communication in this case:

Is the compost granule making system suitable for cow dung biogas waste pellet making?

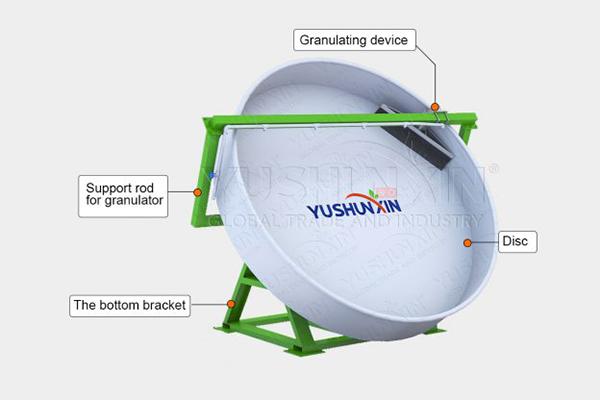

From our page of cow dung fertilizer making, the client from Kenya already had a preliminary understanding of organic fertilizer production. Here, the customer was interested in the solid compost pelleting machines which contain mixing unit, granulating equipment, drying unit, cooling unit and packaging machine.

Is the system suitable for cow manure biogas residue compost granulation? Of course. For using compost as material, the fertilizer pelleting system is an ideal choice. But, it is advisable to add a fertilizer crusher before mixing unit. The machine is used to make cow dung mixture compost into fine powder. So you can finish the compost pellet making easier and faster. In addition, the granule has a more smooth surface.

Which machine is suitable for 50 TPD compost pelleting from cow manure biogas residue?

|

Equipment |

Model | Capacity (t/h) | Disk Diameter (mm) |

Granulation rate |

Powder(kw) |

Dimension(mm) |

|---|---|---|---|---|---|---|

|

Disc granulator |

SXYZ-2800 | 2-3 | 2800 | Over 93% | 11 | 3200*2200*3000 |

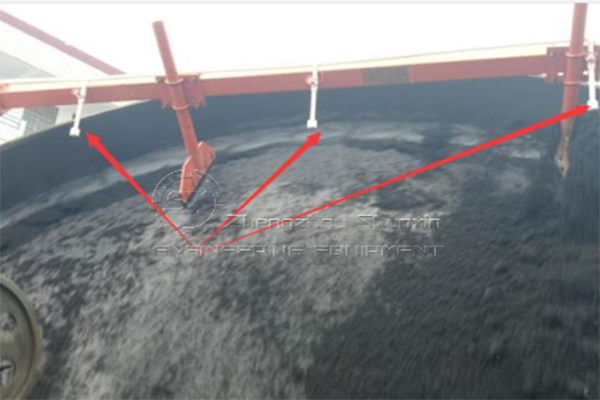

How to change the biogas residue compost pellet size with disc granulator?

In general, during pan granulation process of cow dung biogas waste compost, you can regulate the fertilizer pellets in the following two ways:

The above are details about our communication with the customer about 50 TPD biogas residue compost pelleting machine to Kenya. Besides, we can also offer you many other fertilizer machines. Such as system of organic waste composting machine, manure dehydrator, etc. Welcome to contact us for your own fertilizer business plan.