BB fertilizer making line is an ideal choice to prepare compound fertilizer in a large scale economically. On 22nd February 2024, a customer from Myanmar inquired about this. But the system usually uses chemical granules as material, and the Myanmar client’s material is chemical powder. And the required output is 10 t/h. Can we make compound bulk blended fertilizer from chemical powder? Of course. You can choose our compound bulk blended fertilizer production system with double roller granulators. The following are the specific details of our communication in this case:

Is there suitable equipment to make chemical powder into granules?

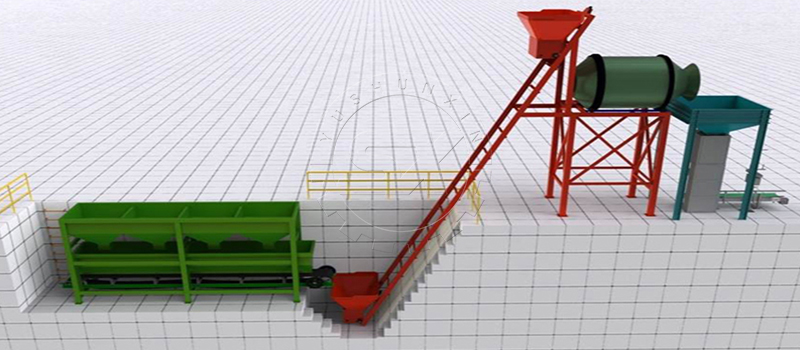

The customer from Myanmar told us that he wanted to start NPK compound fertilizer manufacturing from ammonium sulfate powder. But the bulk blending fertilizer making line he prefers to is using chemical granules as material. So, is there a suitable machine for ammonium sulfate pellets production? Here, it is advisable to add double roller granulation system before the NPK fertilizer mixing system. Why?

Faster chemical granules making

Our double roller granulation equipment granulate NPK powder like ammonium sulfate only by extrusion force between two rollers. No need to take time for chemical powder combination. Therefore, it can make chemical powder into granules faster. In addition, roller pressing method can offer you fertilizer pellets with higher hardness.

No drying and cooling – lower cost

Moreover, there is nearly no water and liquid involved in the fertilizer dry roller granulation process. So, compared with other NPK granulators, you can reduce the cost of dryer and cooler purchasing. Namely, you can finish the production of compound fertilizer with a lower investment.

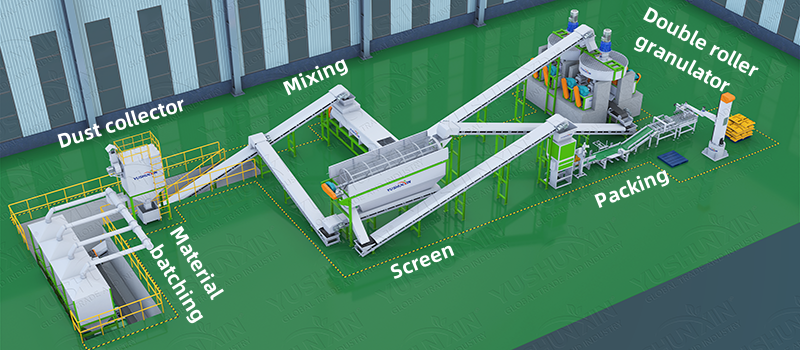

What is the area occupation of the compound bulk blended fertilizer making system?

Then the Myanmar clients focused on the area occupation of the double roller granulation + bulk blending fertilizer system. Because the customer had rented a 600 ㎡ workshop for compound bulk blending fertilizer production. Can the area accommodate the fertilizer machines? The answer is yes. The two chemical fertilizer making systems both have the characteristics of simpler processes and less fertilizer equipment. So, you only need to prepare an area of 500-800 ㎡ for your 10 t/h compound bulk blended fertilizer production project. Including materials area and finished BB fertilizer storage area.

How much does the compound NPK fertilizer machines cost?

Finally, what is the price of the compound fertilizer granulation and bulk blended system? Because of less fertilizer equipment used, the compound bulk blended fertilizer production system has a lower cost. But, due to the differences in capacity, equipment design, dust reduce layout, etc. The cost of 10 t/h roller granulation BB fertilizer line is not fixed. It will change about $50,000-$70,000. If you need a more precise quote for the compound fertilizer system, welcome to contact us and send your detailed requirements immediately.

The above are details about our communication with the customer about compound bulk blended fertilizer production in Myanmar. Besides, we can also offer you many other business plans for compound fertilizer manufacturing. Such as system of making NPK granules from chemical powder, SSP pellets production line, etc.