When you want to dispose of manure in your farm, manure dehydrator is a necessary step. Especially turning fresh animal manure into fertilizer. For one thing, it can reduce the generation of pests and harmful bacteria. For another, it is beneficial for organic fertilizer granules making and manure fertilizer storage. But manual dehydration of manure will take a long time, can we dry manure more quickly? Of course, YUSHUNXIN can provide you with professional manure dewatering equipment. However, is it suitable for you to remove excessive water from manure? For this, you need to learn more about this fertilizer dehydrator. So we especially summarize the top 10 things commonly inquired about manure dehydrator from our customers feedback as follows:

Q 1. What type of manure dewatering machine can SX provide with?

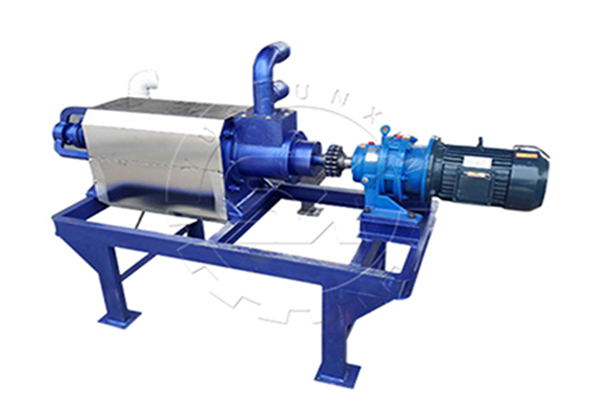

In SX, there are two kinds of manure dewatering machine for your choice. Screw type fertilizer dehydrator and inclined screen solid and liquid separator.

Q 2. Is there a video of the manure solid-liquid separator working?

In SX, there are two kinds of manure dewatering machine for your choice. Screw type fertilizer dehydrator and inclined screen solid and liquid separator.

Q 3. What is the feed manure material moisture?

In general,the lowest feed water content is 50%. In addition, the highest feed moisture of screw type dewatering equipment is 80-90%. But how to remove excessive from manure which has a water content of over 90%? You can use inclined screen solid-liquid separator.

Q 4. What is the moisture after dehydration?

Generally, on the maximum screw pressure, the moisture of organic manure can be reduced to 25-30%; minimum pressure, the moisture is to 35-40%. So the finished moisture after dehydration is about 30-40%.

Q 5. Thickness of screen and hole / slot size of screen

Usually, the screen (body) thickness is 3-4 mm and screen hole size is 0.3-0.5 mm. Moreover, if you need, we can provide you with customized size screen, 0.1-0.3mm. What is the material of the screen? In order to help you dispose of manure into organic fertilizer better, we especially equip manure dewatering machine with stainless steel screen.

Q 6. What is the capacity of a single manure dehydrator?

10-40 m3/h. Moreover, in order to provide you more suitable fertilizer dehydrator, we design different models of manure dewatering machines according to capacity. (technology details are as follows)

| Model | Capacity (m³/h) | Power (kw) | Dimensions (mm) |

|---|---|---|---|

| SXTS-180 | 10-15 | 4 | 1850*650*1150 |

| SXTS-230 | 15-20 | 5.5 | 1850*800*1150 |

Screw type manure dewatering machine parameters

| Model | Capacity (m³/h) | Power (kw) | Dimensions (mm) |

|---|---|---|---|

| SXTSX-800 | 15-20 | 4 | 1700*1500*1300 |

| SXTSX-1200 | 30-40 | 5.5 | 2200*1500*1700 |

Inclined screen solid-liquid separator parameters

Q 7. How to operate fertilizer solid-liquid separator? Can semi-skilled worker operate it?

The operation is very simple, it is controlled by the electric control cabinet. Only need to connect this fertilizer making machine to the power supply after receiving. So even semi-skilled worker can also operate it to dry manure.

Q 9. How much does manure fertilizer dehydrator cost?

Generally, the price of a manure dehydrator is $ 2,000-$4,500.

Q 10. What treatment does manure need to produce fertilizer after dewatering?

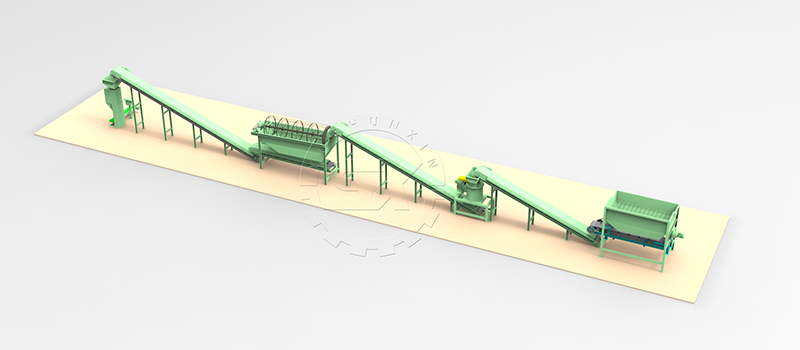

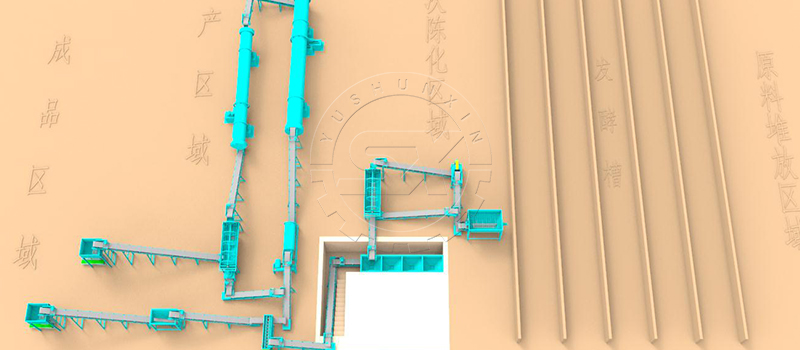

After dewatering, you can further make manure into powder organic fertilizer through composting machine, crusher, screener and packaging equipment. In addition, if you want to make more profits, we also can offer you organic fertilizer pellets making business plan!

The above are top 10 things fertilizer manufacturers want to know about manure dehydrator. If you have any other requirements for manure dewatering, welcome to contact us immediately.