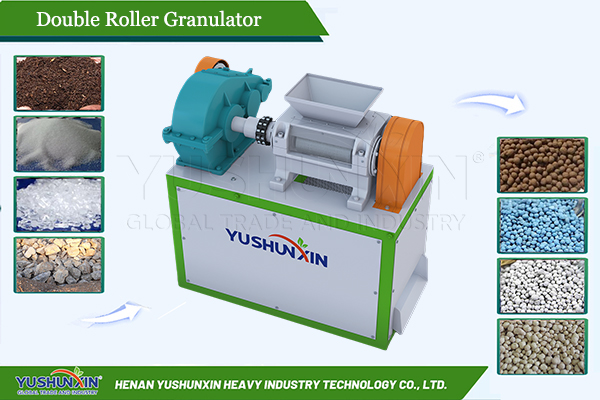

Double roller granulator is favored by many fertilizer manufacturers, especially for NPK granules making plants. Because it makes fertilizer granulation finshing quickly at a low investment. The machine adopts dry granulation method, which mainly makes use of the physical extrusion force between two rollers to turn chemical powder into pellets. In addition, if you want to start a organic fertilizer granulation project, it can also fully meet your requirements. Besides double roller press granulator, we also can provide you with corresponding equipment to form a industrial double roller granulation line for fertilizer manufacturing!

What method does double roller extrusion granulator adopt to make fertilizer pellets?

Are you interested in double roller granulation machine? Do you want to use it in your fertilizer production project? First, it is necessary to learn the granulation method it adopts.

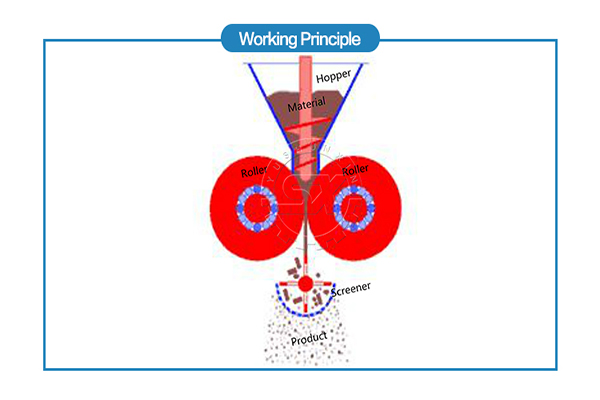

This pellet equipment adopts dry granulation method, which nearly turns chemical material into granule without water. It mainly makes use of extrusion force between the two rollers to granulate compound fertilizer. And the feeding material moisture content must be less than 10%. In this way, there is no need for subsequent drying and cooling. So you can complete the manufacturing of compound fertilizer particles in a simpler process and at a lower cost.

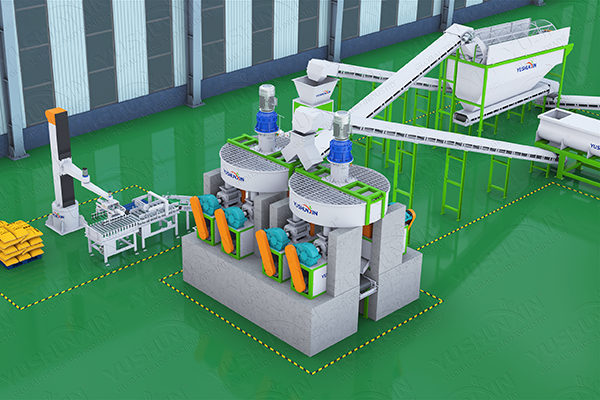

Top 2 Double roller granulator system with 1-20 t/h capacity

In general, there are 2 types of double roller granulation systems most fertilizer pellets manufacturers buy: 1-4 t/h small scale fertilizer granules making line and 4-20 t/h roller extrusion system for large scale fertilizer pelleting.

Technical parameters of YUSHUNXIN double roller granulator

| Model | Power(kw) | Granule Diameter (mm) | Roller Sheet Size (mm) | Dimensions (mm) |

|---|---|---|---|---|

| SXDG-1 T | 15 | 3-10 | 150×220 | 1450×800×1450 |

| SXDG-1.5 T | 18.5 | 3-10 | 150×300 | 1450×800×1500 |

| SXDG-2 T | 22 | 3-10 | 185×300 | 1630×850×1650 |

| SXDG-2.5 T | 22 | 3-10 | 245×220 | 1700×1000×1670 |

| SXDG-3 T | 30 | 3-10 | 200×400 | 1960×980×1760 |

| SXDG-4 T | 37 | 3-10 | 250×400 | 1960×980×1760 |

4-20 t/h roller extrusion system for large scale fertilizer pelleting

When it comes to a over 4 t/h granular fertilizer production project, you can combine 2 or more roller extrusion granulator together. Here, disc distributor can help you divide mixed powder materials to the double roller pelletizers smoothly. In this way, it can fully meet your requirements of 4-20 t/h fertilizer pellets manufacturing. At the same time, you can replace the other machines with a large capacity one. Such as dynamic bathing machine, SXFLF-1000 vertical grinder (10-15 t/h), horizontal mixer, SXGS-2080 sieving machine (10-20 t/h), dual bucket packing machine, etc

3 features of fertilizer pellets under double roller granulation

But the most direct and effective way to choose a suitable granulation machine is testing the finished fertilizer pellet. Then what kind of NPK fertilizer granule can double roller pelletizer produce for you? Usually, the fertilizer granule of double roller granulator has 3 highlights as follows:

How to adjust the pellet size during double roller granulation?

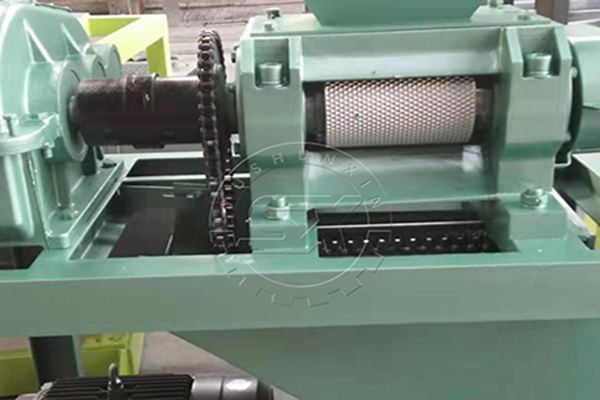

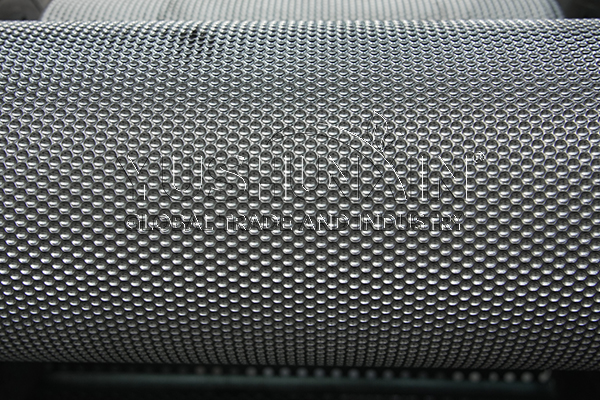

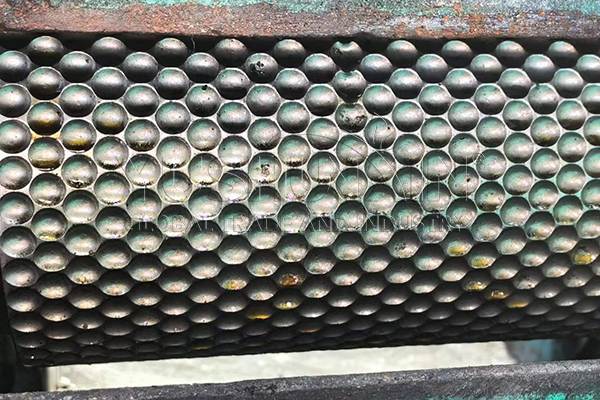

Because of dry granulation method employment, the fertilizer granule size is usually not affected by moisture. Then what is the determining factor of double roller extrusion granulation pellet size? It is the size of ball sockets on the two rollers. So when you want to regulate your compound fertilizer pellet size, the best way is to use rollers with the required size ball socket.

Can we turn roller press fertilizer pellets into round ball?

Of course. You only need to add a fertilizer polishing machine after the roller extrusion granulators. The machine makes use of multiple polishing to make granulated fertilizer more round and has a uniform size.

What are the benefits of using double roller granulator in fertilizer pelleting system?

What kind of fertilizer can double roller press pelletizer produce?

If you want to further know that is double roller granulation machine suitable for you? You need to learn whether it can produce the fertilizer you want? In general, it is suitable for the following occasions:

NPK compound fertilizer manufacturing

In order to supply nitrogen, phosphorus and potassium to crops in a balanced way, it is essential to process NPK fertilizer into granules. Here, double roller granulation equipment is an ideal choice. Whether you want to prepare 20-20-20, 20-10-10 or other NPK fertilizer granules, it can finish the task quickly and easily.

Snow remover granulation

Double roller granulator is also widely used in snow remove agent making. Because after granulation, snow remover is not only more effective, but also easier for packaging, transportation and storage. In addition, using this extrusion pellet making machine, you can turn snow melting agent into granules at a lower cost.

Can double roller granulator make bentonite/organic fertilizer pellets?

Of course. Only the moisture content of the material is lower than 20%. Many powder materials can be processed into fertilizer pellets with roller press granulator. Including compost to organic fertilizer granules and bentonite cat litter pellets production, etc

If you have any other want to know about fertilizer double roller granulation, welcome to contact us now! In addition, there are also many other fertilizer granule making plans for your choice. Such as wet disc granulation line, large scale rotary drum pellet production, etc.