On 25th March 2024, we received a fertilizer manufacturer customer from Bangalore, India in our factory. The client wanted to learn the running of our fertilizer machines and discuss the layout of his 20,000 MT/year bio fertilizer granulating system. The company is engaged in bio-pesticides bio-stimulants, microbials, etc and has primary product of bio fertilizer making – compost powder. But, now, in order to further improve the profits of bio fertilizer making, the customer plans to expand the business to the manufacturing of biofertilizer granules. The following are the specific details of our communication in this case:

Which bio fertilizer granulating machine is suitable for 20000 MT per annum output?

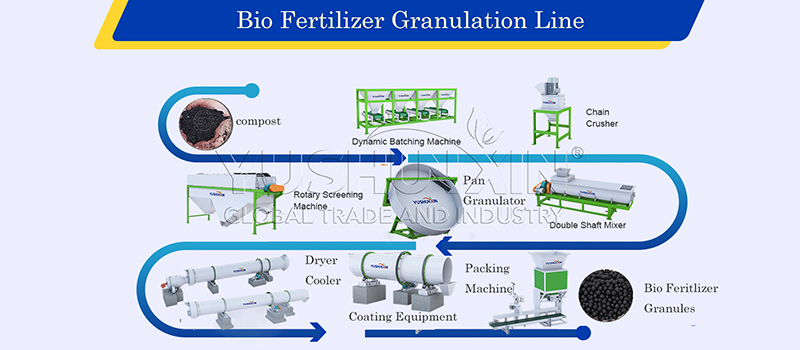

The Indian customer told us that they were looking at capacities of 10000 and 20000 MT per annum. And on 300 days bio fertilizer granule production basis. For this, it is advisable to choose a bio fertilizer granulating system with an output of 2-4 t/h. So there are 2 types of machines that are suitable for you to turn compost into bio organic fertilizer pellets.

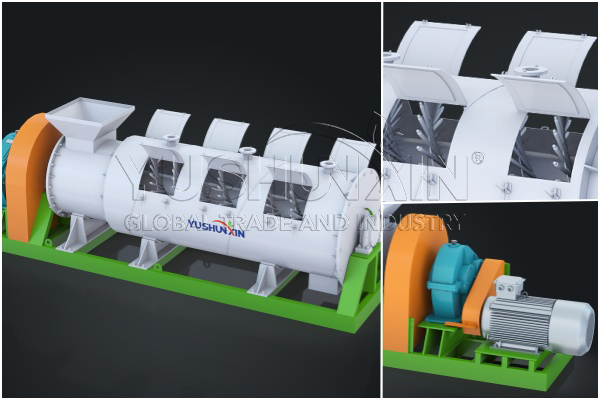

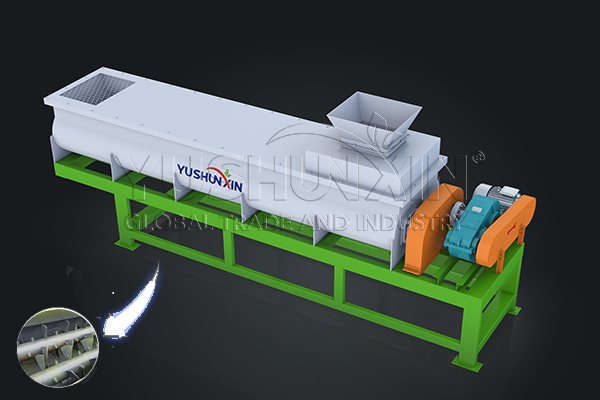

SXJZ-1000 new type organic fertilizer pelletizer – harder granules

For better biofertilizer granule manufacturing with a 2-4 t/h capacity, it is advisable to buy a new type organic fertilizer pellet machine. Because compared to other granulation machines of bio-fertilizer production, it can help you convert compost powder into granule with a higher hardness. And the granulation rate of biofertilizer can reach 97%.

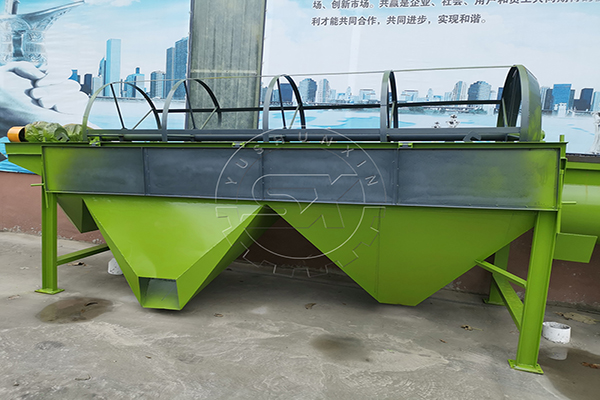

SXYZ-3000 pan granulation equipment – economical cost

However, if you need a 2-4 t/h bio fertilizer granulating system at a low cost, you can choose our SXYZ-3000 pan granulator. You only need to prepare $3,000-$5,000 for our 2-4 t/h capacity disc granulation equipment. In addition, it occupies a smaller area, only 9 ㎡. And if you need, we can offer you pan granulator with water spray device, which can help you control moisture precisely and prepare better bio organic fertilizer pellets.

Finally because of cost limitation, the client from Bangalore, India choose the pan disc fertilizer production.

how to sieve out nonstandard size biofertilizer pellets for reuse?

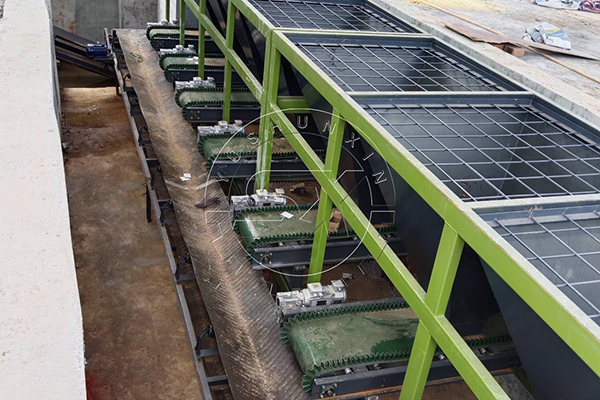

For this, you can process the bio fertilizer granules with rotary screening machine after pan granulation. It can divide the granulated bio fertilizer into 3 parts: small particles and powder, biofertilizer granule with required size, large fertilizer pellets. Then, the standard size bio fertilizer granules will be transported to the next step. At the same time, you can return the nonstandard size pellets to crush and granulate again.

The above are details about our communication with the customer about 20000 MT/year bio fertilizer granulating system in India. Besides, we can also offer you many other fertilizer making business plans. Such as system of fertilizer composting system, fertilizer drying system, etc.