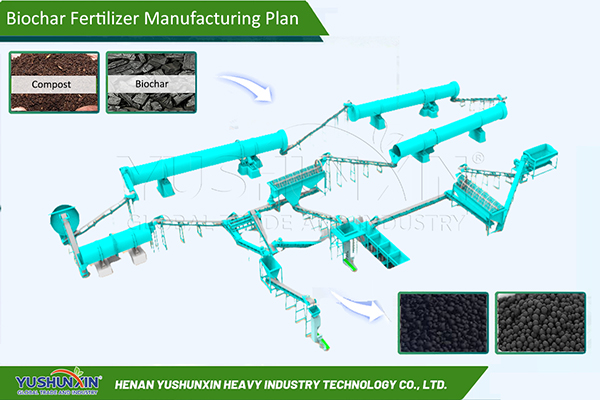

For quality organic fertilizer making, besides bio organic fertilizer production, it is also a ideal choice for mix compost with biochar to prepare carbon-based fertilizer. On 15 November 2023, a customer from Indonesia emailed us for solution to compost and biochar granule making. Here, this client wanted to make the mixture of compost and biochar into pellets, which is 3-5 mm size. In addition, there is a moisture content requirement of final biochar fertilizer granules – being 12% to 15%. So he wanted to buy a system that consists of organic fertilizer granulator and drying machine. The following are the specific details of our communication in this case:

Is there a suitable machine for granulate compost and biochar?

The Indonesian customer had clear requirements for the granulator. The initial moisture of the material mixture is about 35%. Moreover, this client wanted to start compost and biochar granule making with a capacity of 2-3TPH. Here, we designed 2 charcoal fertilizer granulation plans for your choice.

| Model | Capacity (t/h) | Power (kw) | Granule diameter (mm) | Dimensions (mm) |

|---|---|---|---|---|

| SXYZ-2800 Disc Granulation Machine | 2-3 | 11 | 1-8 | 3200*2200*3000 |

| SXDG-3T Double Roller Granulator | 3 | 22 | 3-10 | 1630*850*1650 |

Can the above granulators produce 3-5 mm biochar fertilizer pellets?

Of course. Both the above two machines can prepare 3-5 mm biochar fertilizer pellets for you. Then how to adjust the biochar fertilizer pellet size? For this, these two compost and biochar granulation machines have their own methods.

How to regulate charcoal fertilizer pellets with disc pan pelletizer?

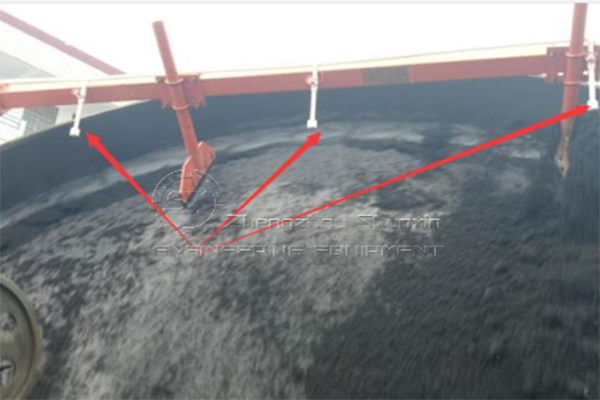

In general, you can adjust the size of final compost and biochar fertilizer granule you make in 2 ways.

Is easy to change biochar fertilizer pellet diameter during double roller granulation?

The answer is yes. Only by using rollers with different size ball sockets, you can make fertilizer particles with the diameter you require. Generally, YUSHUNXIN can offer you rollers for 3-10 mm granular charcoal based fertilizer manufacturing.

Here, in order to flexibly adust the particles size of produced biochar compost granules, the Indonesia customer choose to use a disc granulation plan!

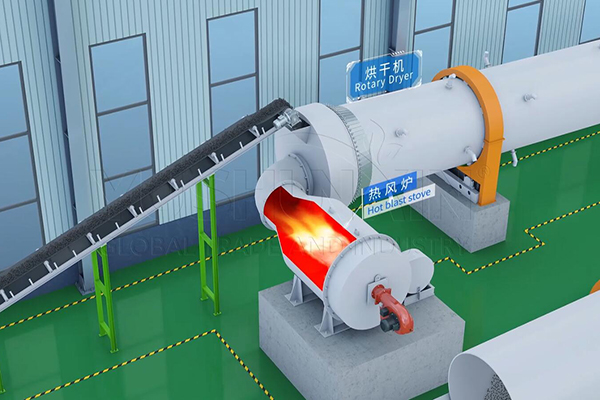

How to dry biochar compost granule moisture to 12%?

Moreover, the client from Indonesia also planned to purchase a dryer for fertilizer pellets. Because this customer wanted to prepare compost and biochar fertilizer granules that have a 12%-15% moist. But, after disc granulation, it is usually about 25%-35%.

| Model | Power (kw) | Reducer Midel | Temp of Inlet (℃) | Angle of Installation (°) | Speed (r/min) | Capacity (t/h) |

|---|---|---|---|---|---|---|

| SXHG-1212 | 7.5 | ZQ350 | ≥300 | 3-5 | 6 | 3-5 |

How much does the biochar fertilizer pellet making line?

Finally, this customer asked about the price of this compost and biochar granule making and drying system. In general the factory price of the biochar fertilizer granulation line is $25,560. Because the customer plan to pay 50% deposit, there is a 5% discount. Finally, it only needs $24,282. The final quote of fertilizer making line is closed related to capacity, equipment number, machine type and model, etc. So, if you want to get precise quote for your biochar fertilizer pellet system, welcome to contact us now!

Is the biochar compost granulation line operating smoothly

Of course. After one month, receiving the system, this client gave us a good feedback of the biochar fertilizer granule making line. “We have start the compost and biochar granule making smoothly. The produced fertilizer is sold very well locally. I want to ordor a crusher, screener and packing machine now, which makes the system working better.”

The above are details about our communication with the customer about compost and biochar granule making in Indonesia. In addition, we can also offer you many other fertilizer business plans and machines. Such as bio fertilizer making line, chemical fertilizer production equipment, fertilizer compost system, etc. Welcome to contact us for your own fertilizer production business plan immediately.