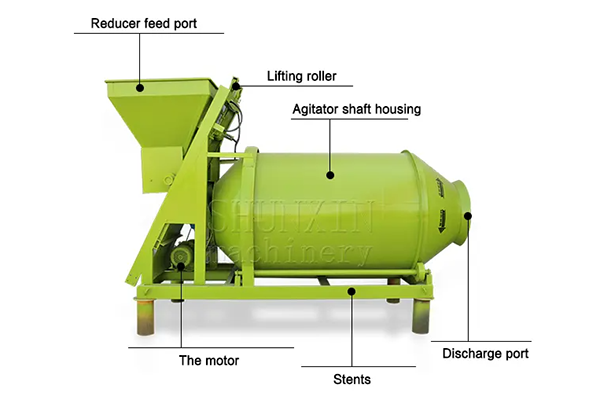

Yesterday, on July 30th 2023, we delivered the double roller granulation line to South Africa. Our work staff of the factory have checked every detail about the delivery. Machine testing, equipment quantity, wooden packing, etc. Because our customer wanted to prepare granular water soluble fertiliser and mix it with other granular pellets. Approx 2 or more tons an hour. This fertilizer granulation line consists of double roller press granulator, BB fertilizer mixer and automatic packaging equipment. The operations are as follows:

Double roller extrusion granulator for powdery materials granulation

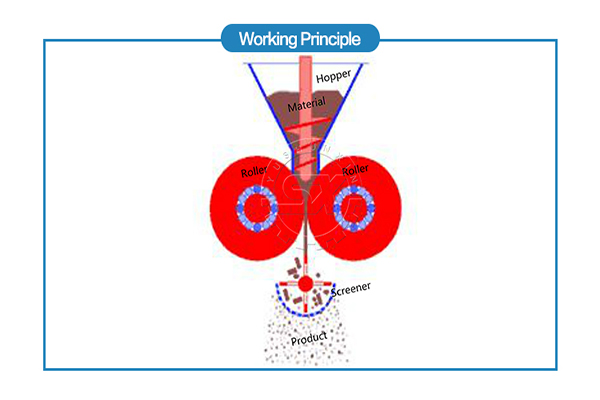

Because the client planned to use powder materials with a moisture content of below 10% directly, double roller granulator is an excellent choice. There are two reasons. On the one hand, it adopts dry granulation method, which mainly relies on the extrusion force between two rollers to granulate water soluble fertilizer. That is, there is nearly no water involved in the fertilizer granulation process. In addition, the feeding material moisture requirement is less than 10%. So it can save your money spent on fertilizer drying and cooling, which is necessary for wet granulation method. On the other hand, the capacity of double roller press granulator is 1-3 t/h, which is exactly what you need, approx 2 or more tons an hour.

This production line is a combination of double roller granulator and fertilizer blending system. Besides, we also can provide you with many other fertilizer making business plans. Such as organic fertilizer making lines, NPK fertilizer granulation system, etc. Shunxin equipment has been available all over the world. We are good at the research and manufacturing of organic fertilizer and compound fertilizer equipment. And we have our own factory and rich export experience. Our equipment all has complete specifications and excellent quality, and the indicators meet or exceed the national standards. so welcome to contact us for details!