Nowadays, for chicken farm management, manure disposal is an item farmers must focus on. In this case, it is an ideal choice to turn chicken poop into organic fertilizer. In this way, you can not only dispose of chicken waste easily, but also make more profits. But how to turn chicken manure into fertilizer? As a professional fertilizer equipment manufacturer, SX can provide you with suitable fertilizer business plans. And we have had many successful cases. For example, on 19th March 2023, a client from Saudi Arabia inquired about organic fertilizer production line for chicken waste. The following are the specific details of communication in this case:

What is the layout of the chicken manure fertilizer production line?

The customer from Saudi Arabia wanted to know the layout of chicken manure organic fertilizer making line. But, here, you need to decide what kind of final fertilizer you plan to produce? Powder? Or granule? The fertilizer equipment used in these two organic fertilizer making business plans is different.

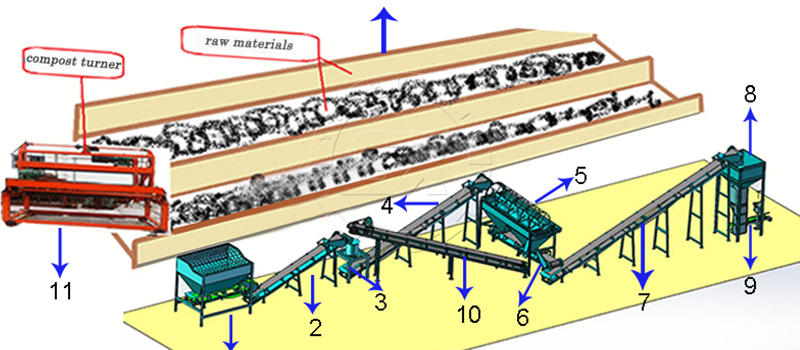

Powdery chicken farm waste fertilizer making line equipment

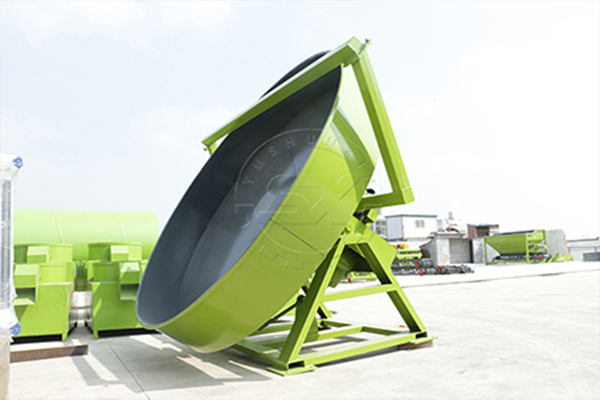

When you want to turn chicken manure into powdery organic fertilizer, you only need to buy several machines. They are chicken manure compost machine, load type feeder, crusher, powder screener, automatic packaging scale and belt conveyor.

Chicken poop fertilizer pellets making system machines

But if you plan to make organic fertilizer granules out of chicken waste, you need to purchase more equipment. In general, a complete chicken litter fertilizer granulation system consists of composter, batching machine, crusher, mixer, powder screener, granulator, granules screener, dryer, cooler, coating machine, bagging equipment and belt conveyor. You can also choose suitable machines according to your needs.

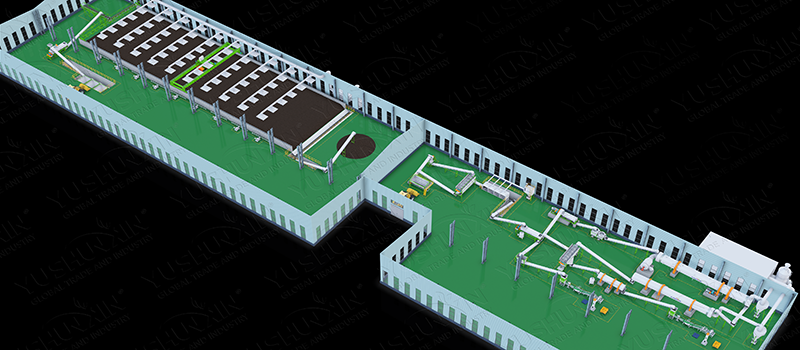

After the above introduction, this Saudi Arabian client asked us if there is a business plan that can prepare organic fertilizer powder and granules from chicken farm waste simultaneously? Of course. We can design two lines after chicken manure compost powder screening. One is for packaging chicken dung powder directly. While another is for chicken poop pellets manufacturing.

How many area does chicken poop fertilizer manufacturing cover?

Then this Saudi Arabian chicken farm owner also wanted to know the area occupation of the system for turning chicken manure into fertilizer. Moreover, can it be accommodated by his workshop?

How to turn chicken manure into fertilizer in a smaller area?

How much does chicken farm waste fertilizer making cost?

Can we start chicken manure fertilizer manufacturing at a lower cost?

The above are details about our communication with the customer from Saudi Arabia. In addition, besides chicken manure organic fertilizer production line, we also can provide you with business plans for other manure management. Such as cow dung fertilizer making plan, pig manure fertilizer production line, etc.