Because NPK fertilizer can supply nutrients for crops in a targeted way, most businesses plan to invest in NPK compound fertilizer production. Like the customer from Indonesia, who inquired about NPK fertilizer making machines on 12th March 2023. Finally, after discussing the details, he chose our NPK double roller granulation line. The following are the specific details of our communication in this case:

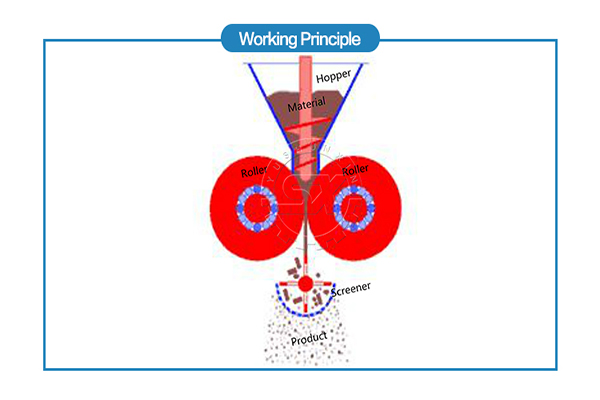

Which granulation machine is suitable for NPK compound fertilizer making?

The client from Indonesia wanted to use Nitrogen (urea), Rock Phosphate, DAP/MAP (depend on Composition), KCL or ZK,clay, dolomite/calcium, coating oil to prepare NPK fertilizer pellets. So first of all, it is essential to buy a type of suitable chemical pellet making equipment.

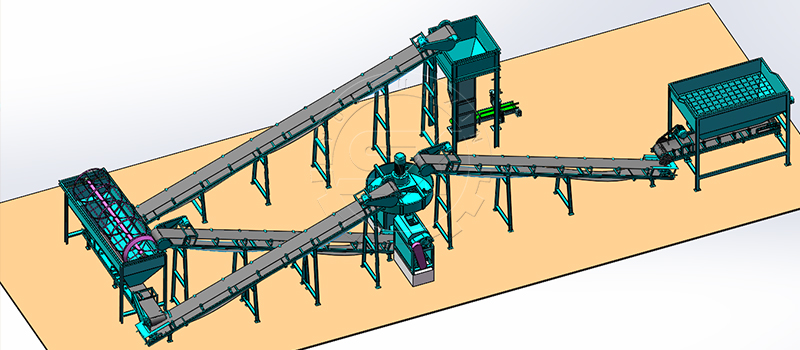

How to design a double roller granulation line which can produce 120 tons of NPK fertilizer per day?

Besides, this Indonesian customer planned to prepare 120 tons of NPK pellets a day. So he asked us can double roller granulation system finish it?

Of course. Because if you keep the double roller pelleting line running 2 shifts a day and 10 hours a shift. It only needs to make about 6 tons of chemical fertilizer particles per hour. Then in general, the capacity of a double roller granulator is 2-3 t/h. Therefore, only by purchasing a system with two double roller extrusion pelletizers can you complete the production of 120 tons of NPK pellets a day easily and quickly.

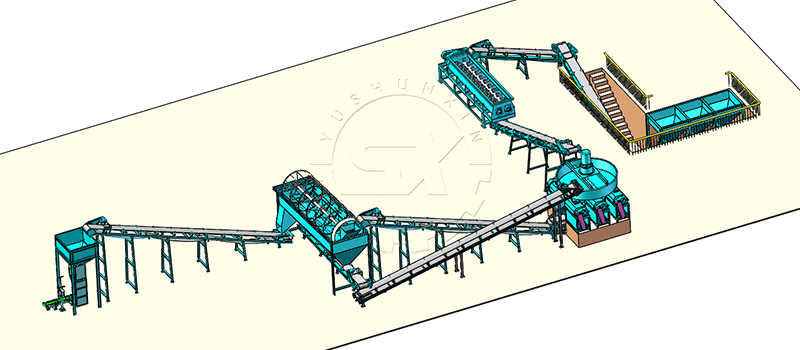

Can I enlarge the NPK granule making business easily when usw double roller granulation line?

The answer is yes! When you want to enlarge your complex fertilizer making business later, you only need to increase the number of double roller granulation machines. For example, if you want to setup a 10-20 t/h NPK double roller granulation line, you can equip it with 4-6 roller press granulators. But for other fertilizer processing machines, including batching machine, crusher, mixer, screener and packaging equipment. You can choose to upgrade them or not freely according to your actual conditions.

How about the final NPK granules of double roller granulation line?

However, the final fertilizer granule is still the best way to test whether the NPK double roller granulation system is suitable for you or not. Hence, the client from Indonesia finally asked us about the following items:

The above are details about our communication with the customer about NPK fertilizer pellet making in Indonesia. In addition, besides double roller granulation line, if you are also interested in pan pellet making or rotary drum granulation, we also can provide you with the best fertilizer business plans!