In Romania, the production of potash and nitrogen fertilizers can fully meet its own needs. However, phosphate fertilizer resources are very scarce. So for those who have stable phosphate material, such as superphosphates, it is an excellent project to invest in. On 11th February 2023, a Techno Service company for oil and gas services inquired about how to start phosphate based NPK fertilizer pellets making in Romania? According to his requirements, we sent a 30 t/h phosphate compound fertilizer granulation line (NPK) . The following are the specific details of communication in this case

How to start Phosphate based NPK fertilizer pellets making in a large scale?

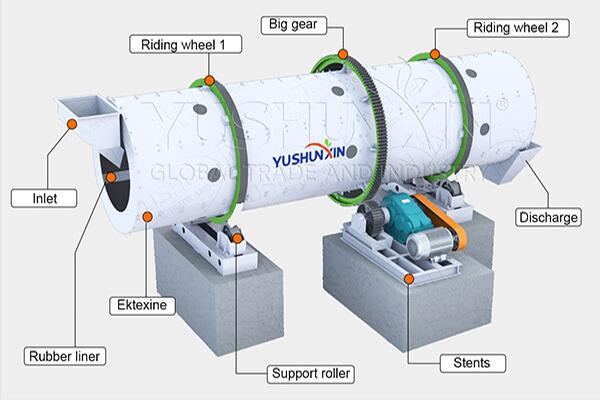

This customer told us that for a project in Romania, he needs a phosphate compound fertilizer production line (NPK) for granulating and the expectant capacity is 20.0-30.0 t/h. Which pelletizer is suitable for this? Here, we recommend you buy a SXZGZ-3210 rotary drum granulator.

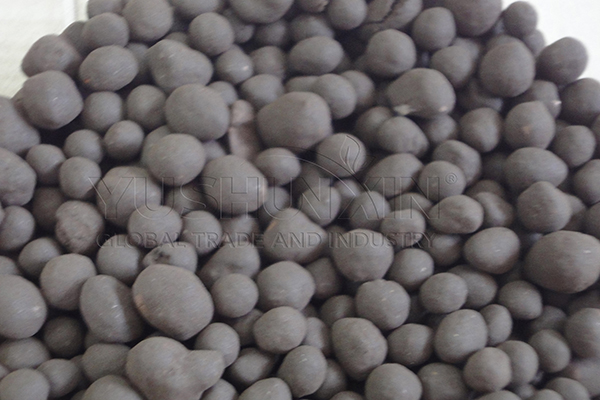

Because the machine can produce 15-30 tons of phosphate fertilizer granules per hour for you. In addition, whether you want to prepare high, medium or low concentration complex fertilizer, it can fully meet your needs. Because we equip it with an extra rubber lining, which has high performance in erosion resistance.

What is the voltage of the phosphate compound granulation equipment?

When you buy equipment for phosphate compound pellets manufacturing, it is also essential to focus on the voltage. After understanding the basic information of compound fertilizer granulation equipment. This Romanian customer paid attention to the voltage. What is the voltage of rotary drum granulator and disc pelletizer? Can it suitable for 220v / 380v / 415v / 440v / 480v (50Hz/60Hz)?

What other equipment is needed in the phosphate compound fertilizer granulation?

Besides phosphate NPK pellet making machines, this customer also wanted to buy some equipment to establish a phosphate compound fertilizer granulation line. They are greatly beneficial for improving the quality of final fertilizer granules.

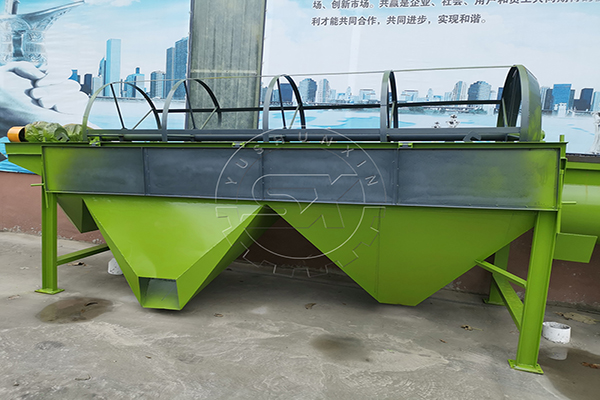

Granules screener

Uniform particle size is an important characteristic of high quality phosphate compound fertilizer. How to separate small or large fertilizer pellets from the required? We can provide you with rotary drum screener for granules. It is able to divide your granular fertilizer into small size, required size and large size. Then you can transport qualified fertilizer to the next process and return unqualified to re-process. In this way, you can produce phosphate compound pellets with high purity and reduce material waste.

Rotary drum dryer

Besides uniform size and high purity, the good transport and storage conditions are also items you need to pay attention to in commercial fertilizer production. For this, it is necessary to buy a rotary drum dryer for your phosphate compound fertilizer granulation line. It will make use of high temperature (300℃) to evaporate the moisture in the fertilizer particles. After drying, the water content of final phosphote fertilizer granule will decrease to 10%. It makes your fertilizer stored for a longer time.

Rotary drum cooler

What do you need to do after drying? Cooling! Why? Because when the dried phosphate compound fertilizer particles are discharged from drying equipment, the temperature can reach 30℃-40℃ . This is not suitable for fertilizer storage and transport. So in phosphate compound fertilizer pellet making line, we usually use a rotary cooler after drying machine.

Coating machine

Then do you want to prepare N/P/K compound fertilizer particles with longer storage time? Du you want to prolong the fertilizer effect of your final pellets? If your answer is yes, we recommend you add coating equipment before packaging. This machine will add a protective film to the pellets, which can isolate fertilizer from outside world conditions.

packaging equipment

Finally, at the end of a phosphate compound fertilizer granulation system, you need to use a packaging machine. It has an automatic weighting system and its quantitative precision is 2 ‰. Therefore, it can help you pack finished phosphate fertilizer into 10 kg, 25 kg or 50 kg quickly. In this way, your fertilizer will be more convenient to transport, store and use. And you can sell them to customers who need different volumes of phosphate compound fertilizer.

The above are details about our communication with the customer about setup a phosphate compound fertilizer granulation line in Romania. In addition, we can also provide you with many other business plans for chemical fertilizer manufacturing. Such as NPK fertilizer production plan, double roller chemical fertilizer granulation system, bulk blending fertilizer making line, etc.