Because of the rising demand for organic fertilizer and the necessity of farm manure treatment, more and more businesses invest in making animal manure into organic fertilizer. For example, on 25th February 2023, a customer from the USA inquired about how to setup a 5 T/H organic fertilizer plant for chicken manure processing. This client told us “…complete line – from receiving raw materials poultry manure from the farm up to packing the granulated fertilizer for chickens manure to produce organic fertilizer. With capacity 5 tons /h…send me the layout, quotation…” The following are the specific details of our communication in this case:

What is the basic equipment of an organic fertilizer making line?

This American customer wanted to buy a complete organic fertilizer making line – from chicken manure collection to fertilizer packaging. With capacity 5 tons /h. Then during the subsequent communications, he asked us what equipment is needed in a complete chicken manure fertilizer production line in detail? In general, it contains the following machines:

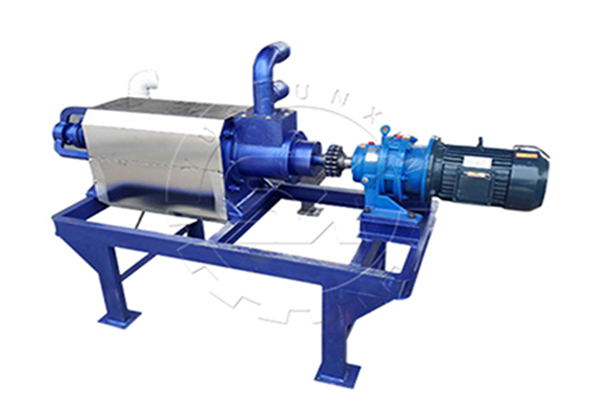

Dewatering machine

Fresh chicken manure usually has a high moisture content, which will affect the production of organic fertilizer. And it is advisable to reduce the water content of chicken dung to below 60%, which is beneficial for better fermentation. Here, dewatering machine can help you finish excessive water removing quickly and easily. And after dewatering, the moisture content of chicken manure is 30%-40%.

Crawler compost turner

For chicken manure recycling, composting is necessary. Because it can eliminate harmful substances in manure, such as pathogens, parasite eggs, grass seeds, smelly odor, etc. Because this customer planned to produce 5 tons of compost from chicken waste per hour, we recommend him choose crawler type compost turner. It adopts windrow composting method and has a turning width of 2.4-3 m and a turning depth of 0.6-1.5 m. So it can process 500-1500 m³ of windrows per hour. In addition, this machine can help you improve the aerobic fermentation effect of chicken manure and finish it within 20 days.

Load type feeder

After composting, you need to transport manure compost into load type feeder. It can filter large stones, grass and other waste from manure and feed it to fertilizer product making system.

Crusher

Do you want to granulate chicken manure easier? Do you hope to produce organic fertilizer with a smooth surface? Crushing machine is indispensable. It can grind compost into fine powder. The finer the powder, the better the granulation effect.

Mixer

In general, besides chicken manure, we also need to add some auxiliary materials to enrich the nutrient content of final organic fertilizer. But adding to chicken litter directly cannot make them play their roles. You need to crush them into powder and mix with chicken manure powder evenly.

Rotary drum granulator

Then it is time to process chicken dung powder into granules. This makes your organic fertilizer more convenient for transport, storage and use. For this process, the USA customers were more interested in rotary drum granulation. Because it has characteristics of high erosion resistance, easy operation and low consumption.

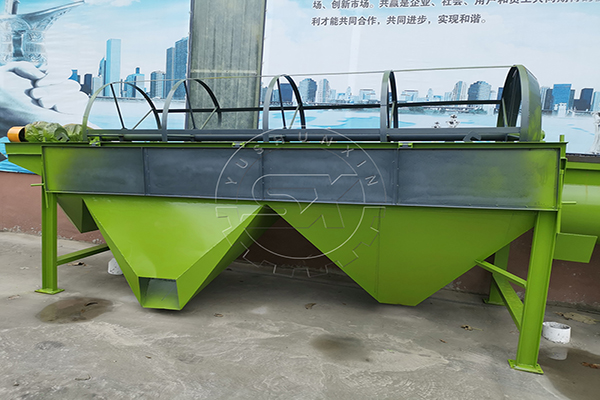

Granule screener

Like powder, after granulation, it is also essential to separate chicken manure pellets with required size from others. We can offer you professional fertilizer granule screening equipment.

Dryer and cooler

Because this organic fertilizer manufacturing line employs wet granulation method. In this way, the moisture content of chicken manure pellet is 15%-20%, which is higher than that of international requirement. So you need to use rotary dryer to remove excessive water. After drying, the temperature of fertilizer particle is 30℃-40℃. This is not beneficial for organic fertilizer storage. So we design cooler to reduce the temperature to a proper level.

Packaging machine

Finally, you can package finished organic fertilizer into 25 kg or 50 kg according to your needs. Our automatic bagging equipment can help you finish fertilizer packing in a short time.

What is the design of a 5 t/h organic fertilizer plant?

When you want to setup an organic fertilizer plant, factory area are also two aspects you must consider. Usually, the whole organic fertilizer making area is divided into three parts:

As the name suggests, this is an area for chicken manure composting. And generally, it will vary with capacity. The larger the capacity, the larger the composting area. For example, the customers from the USA wanted to use crawler type compost machine to prepare 5 tons of chicken waste compost per hour. You need to prepare an area of 1500 ㎡. Can we make compost with a smaller space? Of course. You can choose our fermentation tank, which only needs 10-30 ㎡.

The above are details about our communication with the customer from the USA. In addition, besides organic fertilizer making line, we also can provide you with many other fertilizer manufacturing plans. Such as NPK fertilizer making line, compost fertilizer production business plan, granular fertilizer making system, etc.