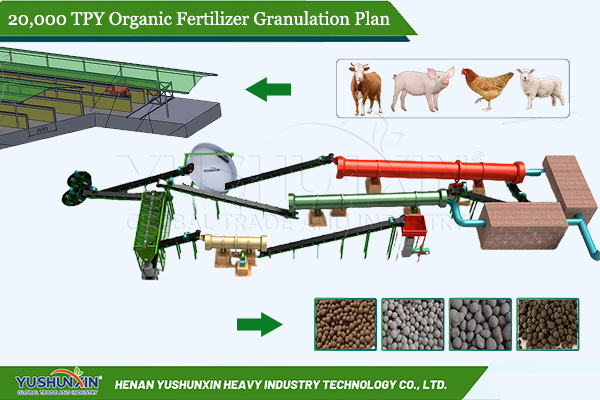

Nowadays, more and more people are prone to invest in organic fertilizer making. Why? One the one hand, because of balanced nutrients content and less pollution, the demand for organic fertilizer grows increasingly. On the other hand, with the booming of husbandry industry, there is a large amount of animal manure needed to dispose of. And making manure into organic fertilizer is an ideal choice. Provided you are a beginner or want to start with small scale organic fertilizer manufacturing, you can buy our 20,000 t/y organic fertilizer production line.

What is the design of a 20,000 t/y organic fertilizer production line?

In general, as a professional fertilizer equipment factory, YUSHUNXIN will design business plan according to your actual conditions. In this process, capacity is an item we must consider. Then what equipment is used in a 20,000 t/y organic fertilizer production line? Commonly, it is advisable to keep fertilizer preparation line running 2 shifts a day and 10 hours a shift. So you need to buy organic fertilizer machines with a capacity of 3-4 t/h. For this, we recommend you purchase the following equipment:

Small scale fertilizer compost turner

When you plan to turn farm manure into organic fertilizer, you need to compost manure to remove harmful substances first. For small scale fertilizer fermentation, many fertilizer suppliers will choose our groove type compost turner or in-vessel fermentation tank. The former is a more economical choice for you while the latter can help you finish manure fermentation more quickly.

Batching machine

Generally, YUSHUXNIXN fertilizer batching machine adopts electric weighting technology. So it can strictly feed various raw materials according to the required proportion. In this way, you can produce organic fertilizer with richer nutrients and higher quality.

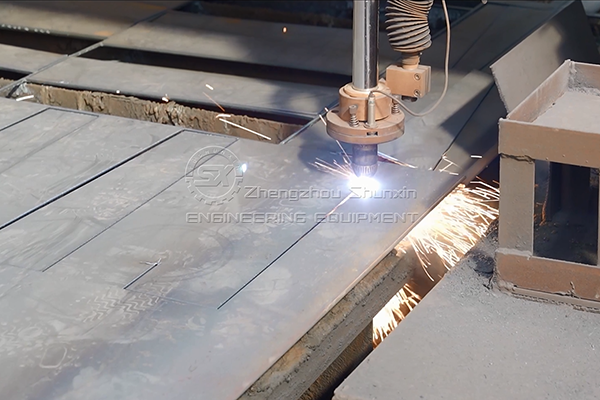

SXFLF-600 new type vertical crusher

Because new type vertical fertilizer shredder employs special steel crushing blades. It have a longer service life and can grind compost into fine powder quickly. In addition, we especially use polypropylene plate as lining and there is no screen mesh. Therefore, it has strong applications for high moisture materials and is not easy to block. The SXFLF-600 vertical grinder has a capacity of 3-5 t/h and power of 22 kw.

Powder screening equipment

In order to prepare better organic fertilizer, screening is necessary. Powder rotary screener can help you separate waste and large particles from fine compost powder. Then the waste (stones, cigarette butts, etc) will be discharged and large particles will be returned to shred again. This is beneficial for improving the purity of final fertilizer product and reducing material waste.

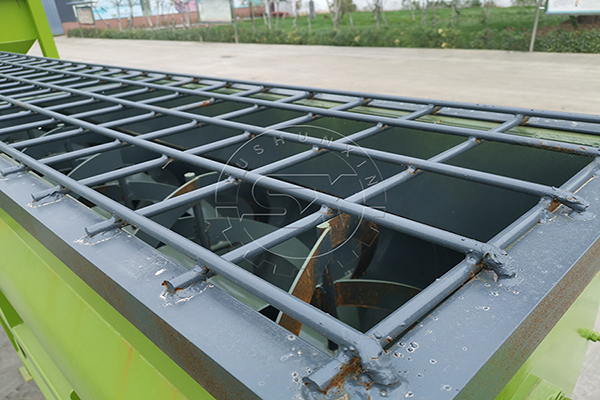

Single shaft horizontal mixer

This mixer processes organic fertilizer with a group of double helical ribbon type blade. It can blend various organic materials evenly. This can ensure you produce fertilizer with balanced nutrients. At the same time, it can process organic fertilizer of 2-5 t/h, which is suitable for 20,000 anuual organic fertilizer making line.

SXYZ-3000 pan pelletizer

For 3-4 t/h organic fertilizer granules production, SXYZ-3000 pan pelletizer is a hot selling product. For one thing, its granulation rate can reach 93%. So you can turn compost powder into pellets more effectively. For another, it has smaller space occupation and favorable price, which make you spend less on 20,000 t/y organic fertilizer manufacturing system setup.

SXHG-1212 rotary dryer

Because of wet granulation method employment, the moisture content of organic fertilizer is about 20% after pan granulation. But for more convenient transport and storage, we usually need to reduce the water content to below 10%. Then how to dry organic fertilizer after granulation? There is professional rotary dryer for you. Its inside hot air temperature can reach 300℃. So it can dry organic fertilizer pellets in a short time.

SXLQ-1212 rotary cooler

After drying, the temperature of produced organic fertilizer is about 30℃- 40℃. So it cannot be packed directly and needs cooling. Here, SX can provide you with SXLQ-1212 rotary cooler, which is suitable for small scale fertilizer cooling.

Automatic packaging scale

Finally, you need to pack organic fertilizer pellets. But manual bagging will take a long time. So we design automatic fertilizer packaging equipment for you. Its quantitative precision can reach 2 ‰ and you can freely choose to pack fertilizer into 10 kg/bag, 25 kg/bag, 50 kg/bag, etc.

Technology parameters of 20,000 T/Y organic fertilizer granulation line

| Equipment | Model | Capacity (T/H) | Power(KW) | Dimension (MM) |

|---|---|---|---|---|

| Groove type compost turner | SXCF-3000 | 3-5 | 18.5+1.5+0.75 | |

| New type vertical crusher | SXFLF-600 | 3-5 | 22 | 1300*750*1900 |

| Single shaft horizontal mixer | 2-5 | |||

| Pan pelletizer | SXYZ-3000 | 2-4 | 11 | 3400*2400*3100 |

| Rotary screener | SXGS-1240 | 3-5 | ||

| Rotary drum dryer | SXHG-1212 | 3-5 | 7.5 | |

| Rotary drum cooler | SXLQ-1212 | 3-5 | ||

| Automatic packaging scale |

How to setup a 20,000 t/y organic fertilizer production plant at a lower cost?

The above is a 20,000 t/y manufacturing line of organic fertilizer granules. And the investment is about $100,000-$170,000. However, can we setup a 20,000 tons/year organic fertilizer production plant at a lower cost? Of course. You can choose fertilizer making business plans as follows:

| Model | Capacity (t/h) | Powder (kw) | Pellet Diameter (mm) |

|---|---|---|---|

| SXPM-400 | 1-1.5 | 30 | 2-10 |

| SXPM-500 | 1.5-2 | 37 | 2-10 |

| SXPM-600 | 2-2.5 | 45 | 2-10 |

Besides 20,000 t/y organic fertilizer making line, YUSHUNXIN also can offer you suitable organic fertilizer making plans with other capacities. Such as 30,000 annual ouput organic fertilizer production line, 50,000 TPY organic fertilizer plant setup, 100,000 t/year organic fertilizer manufacturing project, etc. Welcome to contact us immediately for your own fertilizer business plan.